Aerobic digestion reactors (ADR) for biological wastewater treatmentAerobic digestion reactors are the most competitive choice when effluents have a high concentration of dissolved organic matter due to its low cost and simplicity.

Aerobic digestion reactors (ADR) for biological wastewater treatmentAerobic digestion reactors are the most competitive choice when effluents have a high concentration of dissolved organic matter due to its low cost and simplicity. Technologies to aid ocean conservationOcean conservation is a vital current issue. We analyze some of the main pollutants generated by industrial activities and the possible solutions.

Technologies to aid ocean conservationOcean conservation is a vital current issue. We analyze some of the main pollutants generated by industrial activities and the possible solutions. Photocatalysis or Photocatalytic oxidation (PCO) for VOCs treatmentPhotocatalysis is an advanced oxidation process that has proved to be the most efficient in the treatment of volatile organic compounds (VOCs).

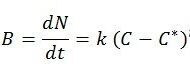

Photocatalysis or Photocatalytic oxidation (PCO) for VOCs treatmentPhotocatalysis is an advanced oxidation process that has proved to be the most efficient in the treatment of volatile organic compounds (VOCs). Salt crystallization in industrial wastewater treatmentSalt crystallization is a very common process in iindustrial wastewater treatment. It also allows the recovery of salts and other raw materials. 98% of clean water can be obtained after a crystallization process.

Salt crystallization in industrial wastewater treatmentSalt crystallization is a very common process in iindustrial wastewater treatment. It also allows the recovery of salts and other raw materials. 98% of clean water can be obtained after a crystallization process. Industrial oily water treatmentThe article analyzes the main technologies for oily water treatment. Oil and water separation is mandatory before pouring or reusing the effluent.

Industrial oily water treatmentThe article analyzes the main technologies for oily water treatment. Oil and water separation is mandatory before pouring or reusing the effluent. VOC Treatment (Volatile Organic Compounds emissions)There are different VOC treatment technologies for industrial activities. These are the most efficient solutions for volatile organic compounds emissions treatment.

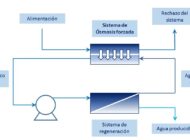

VOC Treatment (Volatile Organic Compounds emissions)There are different VOC treatment technologies for industrial activities. These are the most efficient solutions for volatile organic compounds emissions treatment. Forward osmosis for brine treatmentForward osmosis (FO) is an emerging membrane technology, which is especially suitable for brine treatment and other saline water treatment.

Forward osmosis for brine treatmentForward osmosis (FO) is an emerging membrane technology, which is especially suitable for brine treatment and other saline water treatment. Wastewater treatment in pharmaceutical industryWe have a look at the best available technologies and the most common processes for wastewater treatment in pharmaceutical industry.

Wastewater treatment in pharmaceutical industryWe have a look at the best available technologies and the most common processes for wastewater treatment in pharmaceutical industry. Treatment of effluents generated by the surface-treatment industryVacuum evaporation is a technique that is optimal for a wide variety of effluents and the only viable solution when all the effluents are mixed together.

Treatment of effluents generated by the surface-treatment industryVacuum evaporation is a technique that is optimal for a wide variety of effluents and the only viable solution when all the effluents are mixed together. Treatment of wastewater from paper and pulp industryTreatment of wastewater from paper and pulp industry considering two strategies: water without reuse (open cycle) or zero waste system (closed cyrcle). This latter alternative has two main objectives: to minimize both the water used and the liquid waste generated.

Treatment of wastewater from paper and pulp industryTreatment of wastewater from paper and pulp industry considering two strategies: water without reuse (open cycle) or zero waste system (closed cyrcle). This latter alternative has two main objectives: to minimize both the water used and the liquid waste generated.