Condorchem Envitech offer

Condorchem Envitech designs and manufactures bioscrubbers to treat and eliminate volatile organic compounds, odours and ammonia.

Our bioscrubbers are designed and custom-made for each specific application, with the most common systems being as follows:

- Bioscrubber. Single- or double-stage tower

- Biotrickling

- Bio-desulphurisation

The operating principle of the bioscrubber consists of converting pollutants into carbon dioxide, thanks to the action of our biological activator, which is used to scrub the air inside the tower. In some cases, the water, salts or carbon dioxide generated by bacterial digestion can be reused.

Our bioscrubbers are also highly effective at controlling the odours generated in wastewater treatment processes. In this type of application, an odour removal plant will have to treat not only hydrogen sulphide, but also other pollutants such as ammonia and volatile organic compounds (VOCs) in order to reduce the total odour.

The odour reduction systems that are most commonly used are activated carbon filtration, chemical washing using a traditional scrubber, or biofiltration. These types of plants do not always manage to achieve the required effectiveness in terms of odour units and their operating costs are high compared to bioscrubbers.

Our bioscrubbers

Technical characteristics

- Volume of air treated per tower (from 500 Nm3/hour to 60,000 Nm3/hour)

- Highly efficient odour treatment (>90%)

- Automatic operation via a PLC and HMI screen

- Manufactured with: PP, PVC, PVDF and carbon and stainless steel (304 or 316)

| Flow rate (m3/h) | Dimensions (m) | Power (kW) |

| 1.000 | 1,0 x 1,0 x H 7,0 | 2,5 |

| 5.000 | 1,5 x 1,2 x H 7,5 | 10 |

| 10.000 | 2,0 x 1,5 x H 8,0 | 18 |

| 20.000 | 2,5 x 2,2 x H 8,5 | 36 |

| 30.000 | 2,8 x 2,4 x H 8,5 | 45 |

| 40.000 | 3,4 x 2,8 x H 9,0 | 65 |

| 50.000 | 3,6 x 3,0 x H 9,0 | 88 |

| 60.000 | 3,8 x 3,6 x H 9,5 | 95 |

Benefits

- Highly adaptable to variations in pollutants, including odours.

- Can treat fine particles and low concentrations of ammonia.

- Produces no liquid effluents or by-products.

- Easy operation and maintenance.

- Compact units for small spaces.

- Can be adapted for desulphurisation for biogas scrubbing.

- Unlike a biofilter, the emissions do not need to be humidified before they are treated, saving the cost of installing a humidification system.

Components

- Structure

- Scrubbing solution recirculation system, supplying make-up water and reagents (biological additive)

- Inorganic support filler

- Recirculation pumps

- Process fan (optional)

- Scrubbing ramps

- Sprinklers or spray lances

- Droplet trap

- Electrical panel

Applications

- General industrial odour treatment

- Metallurgical industry

- Biogas scrubbing and upgrading

- Landfills and municipal solid waste (MSW) plants

- RDF (refuse derived fuel) industry

- Composting plants

- Textile

- Ceramics industry

- Oil & gas

- Pharmaceuticals and chemicals

- Food and pet food industry

- Municipal wastewater treatment plants

- Tobacco industry

- Tyre industry

Introduction to the bioscrubber

Bioscrubbers are an absorption technology used to treat gas emissions with a solution of water and biological microorganisms. They can treat emissions that contain acidic and alkaline compounds, fine particles and VOCs that can cause odours.

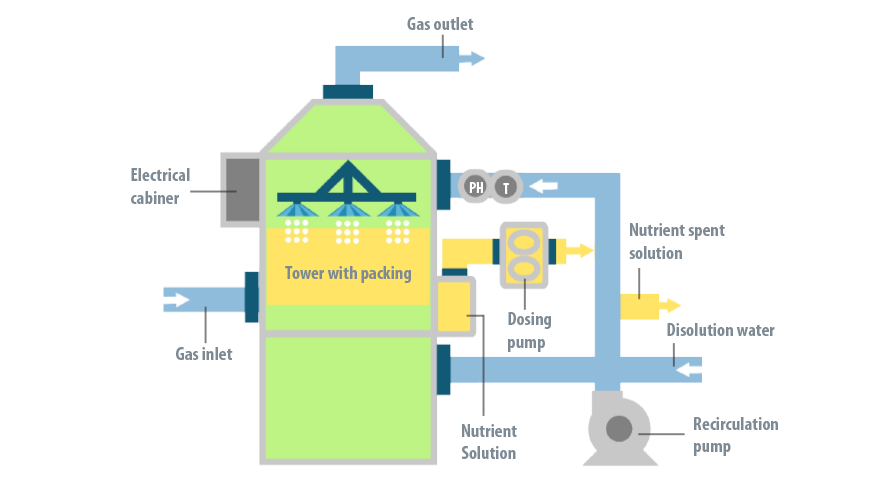

The treatment is carried out by packed tower scrubbers with a scrubbing solution recirculation system.

The scrubbing solution contains suspended microorganisms that act as a reagent. The pollutants are transferred from the gas phase to the liquid phase, where they are used to feed organic matter and are converted into carbon dioxide plus water.

The microorganisms or biological flora adhere to the inorganic support filler and are suspended in the scrubbing solution. These microorganisms use the pollutants as food to reproduce, generating more biomass in the system.

This biomass must be drained regularly and it is the only waste obtained from the process.

This is the same waste that is produced in a biological wastewater treatment plant (industrial ETP or municipal WTP).

It is a highly adaptable and safe system, highly efficient in the treatment of odorous emissions and it does not require much maintenance.

Bioscrubber operation

Contaminated air enters through the side of the bioscrubber and is directed upwards past the packed bed. From the tank at the bottom of the tower, the scrubbing solution is recirculated with the biomass and it is sprayed from the top with spray lances, counter-current to the flow of contaminated gas.

The pollutants pass from the gas phase to the liquid phase, where they are used by the biomass as food, producing an elimination reaction. The clean gas passes through the droplet separator - preventing any entrainment - and leaves through the upper part of the tower.

The recirculated scrubbing solution becomes saturated and the percentage of biomass increases. Timed discharges are programmed to purge small amounts of this biomass, in the same way as in a biological wastewater treatment plant.

The tank has a buoy system to replenish any water lost by the system due to evaporation. It is recommended to wash the internal packed bed once a year to prevent high pressure losses or fouling.

The tower has two openings for inspecting and cleaning its internal parts. The tower is connected to a fan (this may be a blower or vacuum fan) to rectify any drop in pressure in the tower.