Condorchem Envitech Offer

We supply forced circulation evaporators, which are a highly efficient technology for the treatment of industrial wastewater thanks to its low enery consumption.

Our forced circulation evaporators are marketed under the ENVIDEST MVR FC series, with capacities that range from 250 to 2000 liters/hour per modular unit.

Using forced circulation evaporators, the waste present in an effluent can be concentrated efficiently and easily as many times as required, which makes these evaporators a great option for zero liquid discharge systems that need to meet circular economy requirements, such as:

- Reuse of water

- Recover raw materials or by-products

- Minimize energy consumption

- Reduce the amount of waste to be managed

Forced circulation evaporation systems allow the treatment of industrial wastewater that can not be treated with conventional technologies due to the effluent complexity. These evaporators are especially indicated when the effluent to be treated contains fouling substances, viscous liquids, crystals or other components preventing natural circulation.

Introduction to technology

Forced circulation evaporators are extremely efficient in recycling high quality water from an industrial effluent with concentrated pollutants thanks to the application of thermal energy. Forced circulation evaporators operate under vacuum conditions, which reduces the boiling temperature, thereby reducing energy consumption.

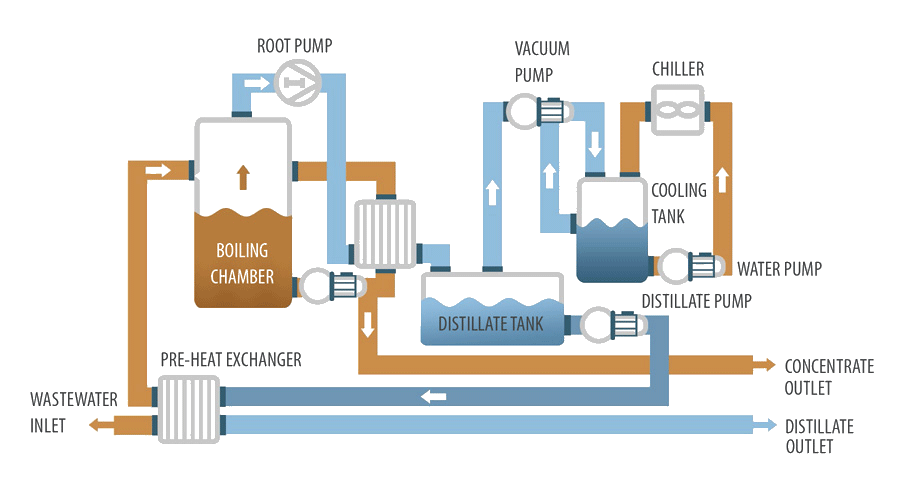

Forced circulation evaporators include a vertical boiler made of AISI 316L. The steam, which is compressed by a root pump, is used to heat the wastewater that needs to be treated thanks to a plate exchanger manufactured in AISI 316L.

Forced circulation evaporators belong to the family of mechanical vapor recompression systems, which have the lowest energy consumption and can treat greater flows (up to 20,000 l/h).

Our forced circulation evaporators

Advantages

- Minimization of the waste volume to be managed

- Significant reduction in waste management costs

- Production of an excellent quality distillate

- Possibility of implementation of a zero discharge system

- Fulfillment of the current regulations on discharge of effluents

- Reduction in greenhouse gas emissions when transporting the waste

- Low maintenance and little need for supervision

Applications

- Water with a high content of oily substances

- Water with a high content of heavy metals

- Water with a high content of dissolved salt

- Dissolved oils and hydrocarbons in contaminated water

- Mixtures suspended in water

- Treatment of leachates

- Degreasing water

Functioning of forced circulation evaporators

The operation of forced circulation vacuum evaporators is based on the recovery of the condensation heat from the distillate as a source of heat to evaporate the feed.

In forced circulation systems, the process starts with the external energy supply to the evaporator to start the evaporation process. The operation of the mechanical vapor recompression evaporators is based on the recovery of the condensation heat from the distillate as a source of heat to evaporate the feed. The steam produced is extracted and compressed by a volumetric compressor with the intention of increasing its temperature. This superheated steam is then returned to the evaporator as a heating fluid. Once the cycle has begun, no more external heat input is required, as the mechanical compression of the steam provides enough heat to maintain the evaporation of the liquid. Upon passing through the exchanger of the evaporator itself, this compressed, and therefore superheated, vapor has two effects: (1) it heats the liquid to be evaporated and (2) it condenses, thereby reducing the need for a refrigeration fluid.

The main advantage of mechanical vapor compression vacuum evaporators lies in the fact that the energy consumption of the volumetric compressor is lower than the cost of producing steam for multi-effect evaporation systems. However, the volume to be evaporated must be high enough so that the saving generated compensates for the investment in the volumetric compressor.

Forced circulation mechanical vapor compression vacuum evaporators have a low energy consumption and can treat high flow rates, up to 2,000 L/h. They are especially useful when the flow to be treated contains fouling substances, viscous liquids, crystals or other components preventing natural circulation.