Condorchem Envitech Offer

We manufacture mechanical vapor recompression evaporators, also known by the acronym MVR evaporators, for the treatment of industrial wastewater and for the management of the sludge generated in other waste water treatment processes, mainly reverse osmosis.

MVR evaporators require low energy consumption for its operation. The high efficiency of this technology is achieved thanks to the use of a steam compressor, which increases the latent heat thanks to the mechanical action of volumetric compression generated by the motor that drives the compressor.

Mechanical vapor recompression evaporation systems offer the following advantages:

- Low power consumption and savings in operating costs.

- Recycling and reuse of treated water.

- Recovery of valuable resources.

- Reduction of solid waste management costs.

These characteristics make MVR evaporators a perfect option for circular economy systems.

Condorchem Envitech supplies three different types of MVR evaporators:

- Natural circulation evaporators: These is very competitive equipment suitable for those cases where low steam production is required, 10-120 L/h.

- Falling film evaporators: These are the latest generation evaporators, with a cleaning system integrated in the equipment which can produce up to 4,000 L/h.

- Forced circulation evaporators: This mechanical vapor compression equipment has the least energy consumption and can treat greater flows (up to 20,000 L/h).

At Condorchem Envitech, we have three types of mechanical vapor compression vacuum evaporators:

- Envidest MVR E de natural circulation evaporators for flow rates from 10 L/h up to 120 L/h.

- Envidest MVR FF falling film, or flow film, evaporators for flow rates up to 4,000 L/h.

- Envidest MVR FC forced circulation evaporators for flow rates up to 20,000 L/h.

For larger treatment volumes, modular configurations can be used with several machines working in parallel.

Our MVR evaporators

Advantages of mechanical vapor recompression systems

- Minimization of the waste volume to be managed

- Significant reduction in waste management costs

- Production of an excellent quality distillate

- Possibility of implementation of a zero discharge system

- Fulfillment of the current regulations on discharge of effluents

- Reduction in greenhouse gas emissions when transporting the waste

- Low maintenance and little need for supervision

Applications

- Industrial painting: baths for degreasing, phosphating, passivation, washed water and eluted ion exchange resins.

- Metalworking and car parts industry: surface treatment baths, wash baths, finishing vibro water, compressor purges, water washed floors, oil emulsions.

- Die casting metals and light alloys: e.g. demoulding fluids, glycols and oil emulsions.

- Chemical industry: Reactor washing.

- Leachate at MSW landfills.

- Water treatment plant reject fractions in power plants (e.g. reverse osmosis and demineralizers)

- Metalworking and car parts industry: surface treatment baths, parts washers, finishing vibro water, compressor purges, water washed floors and lubro-refrigerant oil emulsions.

- Die casting metals and light alloys: e.g. demoulding and oil emulsions.

- Salt water and brine.

- Water with a high content of oily substances.

- Water with a high content of heavy metals.

- Water with a high content of dissolved salt.

- Dissolved oils and hydrocarbons in contaminated water.

- Mixtures suspended in water.

- Treatment of leachates.

- Degreasing water.

Introduction to the technology

A mechanical vapor recompression vacuum evaporator is designed for the efficient treatment of industrial waste effluent from production processes and water treatment plant reject fractions (brine) with a low energy cost. Its high efficiency is due to the use of a rotary blower or steam compressor, which increases its latent heat by the mechanical action of volumetric compression with a small amount of electrical energy used in the motor powering the compressor.

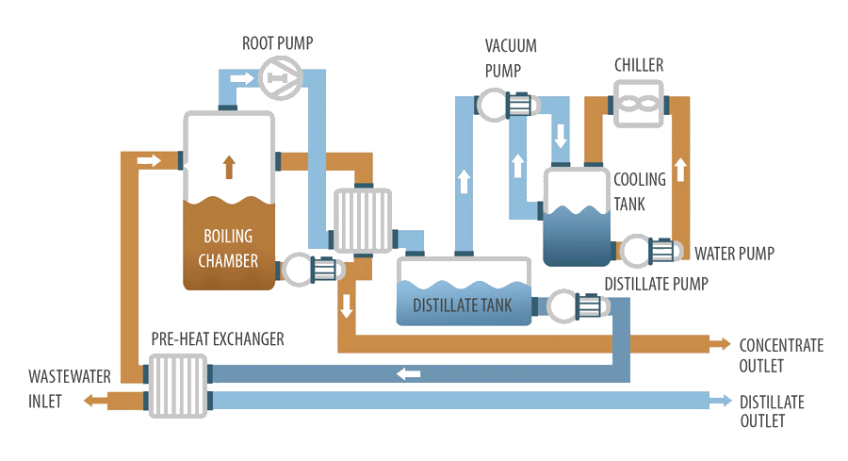

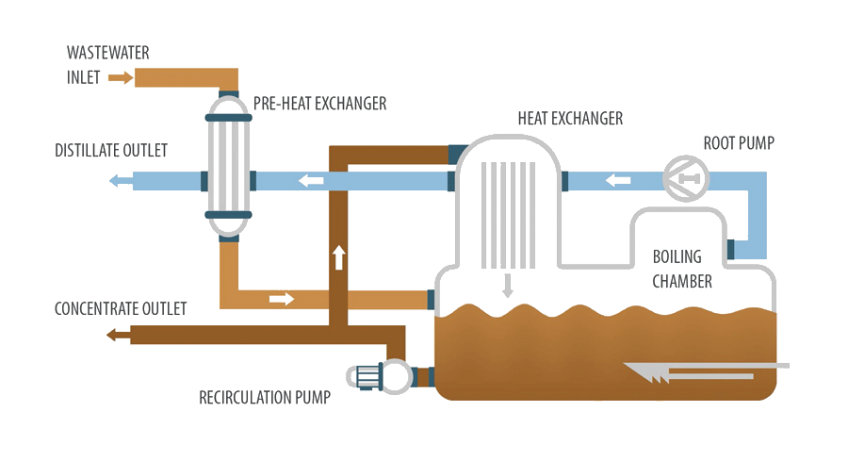

This heat from the compressed steam is supplied by a heat exchanger to heat the effluent to evaporate and consequently condense the vapor to produce distilled water. When working under vacuum, produced by the rotary blower itself or by an auxiliary vacuum pump, the boiling and steam temperatures range from 60°C to 90°C.

Vacuum evaporators separate high quality water from a relatively concentrated contaminant phase by the application of thermal energy. Working under vacuum means the boiling temperature can be reduced, thus reducing energy consumption.

By using vacuum evaporators, waste effluent can be concentrated efficiently and easily as much as required, up to zero discharge if required. This technology can treat effluents which are not effective or viable to treat by the most conventional techniques due to their nature.

Functioning of MVR evaporators

Equipment operation

The operation of the mechanical vapor compression vacuum evaporators is based on the recovery of the condensation heat from the distillate as a source of heat to evaporate the feed.

In these systems, the process starts with the external energy supply to the evaporator to start the evaporation process. The operation of the mechanical vapor compression vacuum evaporators is based on the recovery of the condensation heat from the distillate as a source of heat to evaporate the feed. The steam produced is extracted and compressed by a volumetric compressor with the intention of increasing its temperature. This superheated steam is then returned to the evaporator as a heating fluid.

Once the cycle has begun, no more external heat input is required, as the mechanical compression of the steam provides enough heat to maintain the evaporation of the liquid. Upon passing through the exchanger of the evaporator itself, this compressed, and therefore superheated, vapor has two effects: (1) it heats the liquid to be evaporated and (2) it condenses, thereby reducing the need for a refrigeration fluid.

The main advantage of mechanical vapor compression vacuum evaporators lies in the fact that the energy consumption of the volumetric compressor is lower than the cost of producing steam for multi-effect evaporation systems. However, the volume to be evaporated must be high enough so that the saving generated compensates for the investment in the volumetric compressor.

There are different mechanical vapor compression vacuum evaporator designs, with the most competitive being the following: