Sections

- Emulsions: wastewater with oils

- How are oily emulsions formed?

- Wastewater with emulsified oils

- Problems of oily wastewater

- Technologies for treating wastewater with oils

- Conclusions

Emulsions: wastewater with oils

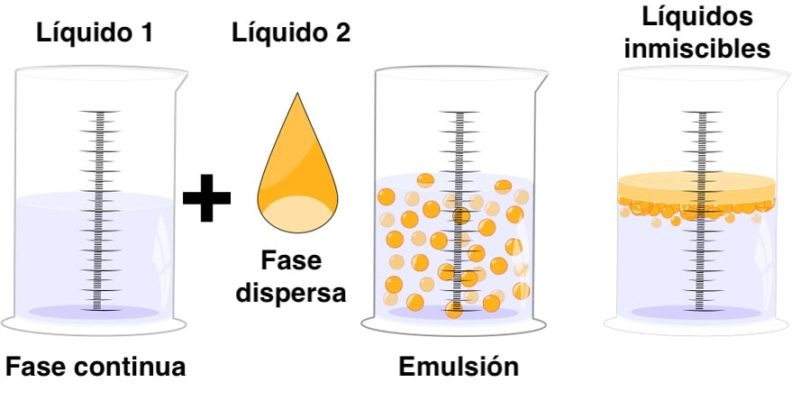

An emulsion is a mixture of immiscible liquids. It is a suspension of small droplets of one liquid dispersed in another liquid. Emulsions differ from other colloids because they always consist of liquid phases.

Emulsions are classified according to the size of the dispersed droplets as follows:

| Emulsion | Droplet Size |

|---|---|

| Macro emulsion | 0.2 – 50 mm |

| Micro emulsion | 0.01 – 0.2 mm |

There are three essential requirements to form an emulsion:

- Two immiscible liquids

- Sufficient agitation to disperse the liquid into small droplets.

- An emulsifier to stabilize the dispersion.

There are compounds, such as surfactants, that are emulsifiers (or emulsifying agents), meaning they keep two immiscible substances mixed.

How are oily emulsions formed?

In the case of water and oil, emulsions are caused by agitation in the mixture as the oil breaks up in the liquid and disperses in the form of small droplets.

Interfacial tension favors the phenomenon of coalescence in the dispersed droplets, thereby reducing their total area.

According to their combination, emulsions are classified as:

- Direct emulsions. Emulsions that combine a lipophilic dispersed phase (attracted to fats) and a hydrophilic continuous phase (attracted to water).

- Inverse emulsions. Emulsions that combine a hydrophilic dispersed phase and a lipophilic continuous phase, i.e., the reverse of direct emulsions.

- Multiple emulsions. Emulsions that present an inverse emulsion as the dispersed phase and an aqueous liquid as the continuous phase.

The two phases that make up an emulsion are always distinct and are classified as:

- Continuous phase. The phase that is predominant over the other, i.e., the one within which one of the liquids that make up the emulsion is dispersed. It is also called the “dispersing phase.” In the case of oily emulsions, the continuous phase is water.

- Dispersed phase. The phase that is minority compared to the other, i.e., that is dispersed within the dispersing phase. In this case, the oil.

Wastewater with emulsified oils

In industrial applications, oily emulsions are generated in situations such as:

- Water contaminated with hydrocarbons.

- Water injected into drilling wells to displace oil.

- Lubricant in machining processes to reduce wear on metal parts.

- Rinsing water in galvanic and surface treatment processes.

There is a wide variety of activities and industrial processes that produce oily wastewater.

- Oil extraction

- Refineries

- Mining activities

- Bilge effluents and ballast water from vessels

- Aerospace and vehicle maintenance stations

- Leaks from oil processes

- Stormwater runoff

- Mechanical workshops

- Meat processing and poultry farms

- Fish processing

- Dairy processing

- Paint production

- Soap and detergent production

- Textile industries

- Chemical industries

Problems of oily wastewater

Oily effluents can have a significant impact on the environment, making it crucial to manage them properly to protect both our health and that of aquatic ecosystems.

Here are some dangers of improper management of oily wastewater:

Water pollution

When oils and fats are discharged into points such as rivers, lakes, or seas, they pollute the water. This can harm aquatic life and affect species that depend on these ecosystems.

Disruption of ecological balance

Oily effluents disrupt the natural balance of aquatic ecosystems. This affects organisms living in the water, such as fish, birds, and aquatic plants.

Additionally, the accumulation of oils on the water’s surface can hinder oxygenation and the entry of sunlight, affecting photosynthesis and the food chain.

Diseases and toxicity

Oils and fats can contain toxic substances, such as heavy metals or chemicals. These contaminants can be absorbed by aquatic organisms and ultimately affect humans who consume them.

Moreover, toxicity increases the likelihood of organisms becoming ill.

Impact on biodiversity

Oil pollution can reduce biodiversity in aquatic ecosystems. Some species may not survive or may leave the area due to the presence of oils. This affects the diversity and stability of the ecosystem.

Acidification and climate change

Oily effluents often contain greenhouse gases, contributing to climate change. Additionally, they can increase the acidification of oceans, affecting corals and other marine organisms.

Technologies for treating wastewater with oils

With this type of effluent, whether the intention is to discharge it into the public sewer system or to reuse the water, an efficient system for treating oily emulsions will be necessary.

These oily wastewater treatment plants usually combine different technologies, the design and selection of which will depend on various factors such as the composition of the wastewater or the client’s objectives.

The most efficient technologies for separating water from oil are as follows:

Dissolved Air Flotation (DAF)

This technique allows for the separation of emulsified oils in water. To do this, part of the treated effluent is collected and pressurized in a tank with air, then released through a manifold system, generating microbubbles of about 50 μm in size. These bubbles adhere to suspended particles and make them lose apparent weight, causing them to float, also utilizing the phenomenon of coalescence.

Before treating the discharge through flotation, the colloids that constitute the emulsion must be destabilized. To do this, coagulant reagents, such as aluminum sulfate or ferric chloride, are added to neutralize the charges of the colloids, thus facilitating the formation of small flocs or clots.

After coagulation, flocculation is carried out by adding a flocculating reagent, which is usually long-chain polymers (polyelectrolytes). The obtained flocs have a size and density that allow their separation by DAF flotation. For these processes to develop adequately, they must react in tanks that facilitate the appropriate contact and agitation regime, or in a flocculator that provides the turbulent regime and contact time necessary for optimal efficiency.

Vacuum evaporation

The evaporation process is the only one that allows for the separation of oil from water without the need to pretreat the effluent and without requiring further processes, as the water produced by vacuum evaporators is of high quality and can be reused directly.

Regarding the waste, unlike other systems, such as membrane separation, no other residual effluent is generated after the evaporation process. A semi-solid waste is obtained that can be valorized in other processes due to its composition.

Another significant advantage of vacuum evaporation for treating oily wastewater is its high adaptability to the changing characteristics of the effluent to be treated, making it a robust and effective alternative. Additionally, operating under vacuum conditions keeps energy consumption low, achieving high energy efficiency.

They are compact units, and generally, significant physical space is not required for their installation. Their use is straightforward and can be automated. Without a doubt, it is the best alternative for treating oily effluents.

Biological treatment

The removal of oils and fats through biological degradation presents a series of difficulties that complicate the process, both under aerobic and anaerobic conditions.

Firstly, oil and fats do not have a composition that allows for their biodegradation unless chemical products are dosed beforehand or mixed with other waste, so that microorganisms can obtain all the nutrients they need for growth.

Secondly, the biological process does not handle fluctuations in flow or input load well. Additionally, in an aerobic process, the biodegradation of oils and fats entails a high oxygen consumption, which requires a significant energy input and high operating costs. Finally, due to its complexity, the operation of this process requires qualified operators.

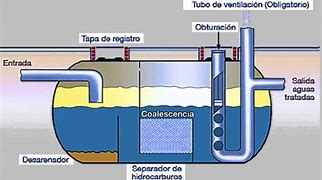

Coalescence separators

In the coalescence process, the separation of an emulsion into two immiscible phases occurs in three stages: collection, coalescence, and gravity separation. The introduction of the coalescing medium is carried out to improve the collection and coalescence processes.

The capillarity and wet characteristics of the medium contribute to the drop-by-drop coalescence that occurs once the drag is collected in a destination location.

The gravity separation that takes place downstream of the coalescing medium depends mainly on the geometry of the vessel and the “start-up” and residence time of the dispersed phase.

A plate coalescer is used in the liquid section of a separator or clarifier to optimize the degree of liquid-liquid separation. The flow through the narrow spaces between the plates is laminar, and the droplets separate because the distance that the dispersed phases have to travel to the interface is greatly reduced.

The plates are grouped in a small compartment that fits into the main flow path. The operating principle of parallel plate separators is based on the difference in density between the oil and water phases: oil droplets in the aqueous phase rise to the oil/water interface, while water droplets in the oily phase remain.

For dispersions of up to 50-100 microns, efficient separation can be achieved with this technique, and it is the appropriate equipment design in contexts with potential for solids or tarry liquids. Oil/water separation and removal of diesel and kerosene mists. Its oil reduction performance is not very high, but it has applications in certain sectors (gas stations, runoff, pre-separations, etc.).

Vibrating membranes (VSEP)

The use of filtering membranes allows for the production of high-quality water from any oil-in-water emulsion.

However, membrane filtration has a weak point, which is its fouling, which is difficult to reverse, and is due to the formation of a dirt layer that may consist of a biofilm, organic matter, inorganic deposits, or colloidal nature, etc. This layer accumulates on the membranes during the filtration process and decreases the treatment efficiency of the membranes.

To address this problem, VSEP vibrating membranes have been developed. This is an alternative technology that cleans the membranes by producing shear waves tangent to the membrane surface. The vibration of the membrane and the production of shear waves cause the solids deposited on the membrane surface to reintegrate into the liquid and be carried away by it, exposing the membrane pores to the liquid again.

A significant difference compared to conventional static membranes is that the basic design is vertical instead of horizontal, which means that the space required per unit is less than in other separation systems.

Additionally, to extend the lifespan of these membranes, it is advisable to pre-treat the feed water. As in any membrane process, their care, cleaning, and maintenance are very important factors to ensure optimal performance and longevity.

This technique, while generating a flow of high-quality water, also produces a concentrated effluent that requires subsequent management.

Ceramic membranes

This is a very efficient technology for the removal of oils and fats, as these membranes are characterized by their high hydrophilicity, attracting water and rejecting oil. This behavior allows for obtaining a high-quality filtered effluent.

It is a robust and compact technology that allows for obtaining water suitable for reuse in certain applications. Additionally, this water can be treated with reverse osmosis if it is necessary to remove dissolved salts.

Permeate flows are significantly higher than those obtained with polymeric membranes, which are hydrophobic in nature. The high mechanical, thermal, and chemical resistance of the ceramic material also stands out, allowing operation under extreme pH and temperature conditions (for example, in the treatment of degreasing baths).

The operability of ceramic membranes is measured by cycles, as the membranes become fouled, and every predetermined time, a chemical wash must be performed, which usually uses very aggressive reagents to restore the operating conditions of the system. Additionally, since it is a tangential filtration system, it must operate at very high recirculation flows to prevent blockages, which leads to costly installations and high energy consumption.

Electrocoagulation

This technology works by supplying a current to a series of metal electrodes. The anodes oxidize, releasing metal ions into the electrolyte. These ions neutralize the charge of the solution and destabilize it.

In the case of oily wastewater, the metal ions will serve to destabilize the oil and water emulsion, allowing the oil droplets to join (coalescence) and rise to the surface. The separation is also aided by the cathode. While the anode oxidizes, the cathode produces bubbles that assist in the flotation of these particles.

Electrocoagulation facilitates the operation, use, and maintenance of the reaction tanks, as no chemicals are required for destabilization. As an additional benefit, it also produces much lower volumes of sludge that can often be reused for various applications.

The main obstacle of coagulation is its limitation regarding the variety of oily wastewater it can treat.

Conclusion

Oily emulsions must be treated prior to discharge due to their high contaminating potential, which affects both the environment and ecosystems.

There are different processes that can separate oil from water and even produce a high-quality water effluent optimal for reuse. Among all possible alternatives, the one with the greatest advantages is vacuum evaporation, due to its simplicity, flexibility, robustness, and effectiveness.

Bibliography and inquiries

https://concepto.de/emulsion-quimica/

https://www.tecnoaqua.es/media/uploads/noticias/documentos/articulo-tecnico-filtracion-ceramica-tratamiento-reutilizacion-aguas-aceitosas-origen-industrial-tecnoaqua.es_.pdf

COALESCEDORES / SEPARADORES LÍQUIDO-LÍQUIDO (awscorp.it)