Our biogas upgrading system

CLEAN-BGAS UPGR is a highly efficient solution for biogas upgrading and biomethane production. The system is composed of different stages and it is based on a chemical process which includes a chemical scrubber with amine. The technology has different modules:

- Biogas Cleaning

- CO2 removal / Biomethane. CO2 removal / Biomethane production

- Solvent recovery

- Drying gas/biomethane

Our equipment

CLEAN-BGAS UPGR

Biogas Cleaning: It aims to separate all the impurities from the biogas before its entry into the CO2 removal process. At this stage undesirable compounds such as siloxanes, moisture, particulates, halogenated hydrocarbons and NH3, that can poison the solvent used for scrubbing, are removed.

CO2 removal / Biomethane. CO2 removal / Biomethane production: This is performed by chemical absorption. The biogas is washed with a suitable chemical solvent (alkanoamina) to remove up to 100% of CO2 from this stream, as well as possible traces of H2S that can be found in biogas. As a result of the process, a biogas stream with a high level of CH4, similar to natural gas is obtained.

Solvent recovery: The regeneration of the solvent is made by distillation. By doing so the CO2 stream is removed from the solvent, captured from the biogas. The solvent is once again used in the absorption operation while the CO2 can be destined to other uses (filling fire extinguishers, dry ice, seaweed farming, petrochemicals, etc.).

Drying gas/biomethane: Its purpose is to ensure a dry gas for its compression and storage. This operation involves cooling and drying by adsorption. For the last operation, substances with a high adsorption capacity are used.

Advantages

- Low power consumption

- Minimum investment in civil works

- Ecological fuel

- Operation at low pressures

- The solvent is selective, minimal loss of methane

Applications

- Biofuel for vehicles

- Injection into natural gas grid

- Raw material for production of methanol and hydrogen

- High purity CO2

- As natural gas

Technical features

- Suitable for any type of biogas.

- Compact equipment installed in modified shipping containers.

- Modular equipment depending on the vehicle fleet.

- Operates at low pressures.

- Intelligent management of energy produced.

- Fully automatic.

- Produces a high CO2 concentration stream useful for the market.

Components of our biogas upgrading plant

- Blower

- Coolers

- Active carbón filter

- Particle filter

- Absorption tower

- Drying towers

- Regeneration of drying towers

- Desalination tower

- Distillation tower

Biogas upgrading technologies for biomethane production

At present, we can speak of two basic types of biogas. The first is biogas that is produced in a controlled way. This is based on anaerobic digestion technology usually involving different types of bio-digesters, depending on the material to be treated. The other is biogas produced in a natural (uncontrolled) way and at the moment this occurs most commonly at MSW landfills.

Table 1 shows the typical composition of biogas in accordance with its origin, i.e., the material treated.

| Gases | Agricultural Waste (%) | WWTP Sludge (%) | Industrial Waste | MSW Landfills (%) | Effect |

|---|---|---|---|---|---|

| Methane | 50-80 | 50-80 | 50-70 | 45-65 | Combustible |

| CO2 | 30-50 | 20-50 | 30-50 | 34-55 | Inert |

| Vap H2O | Saturation | Saturation | Saturation | Saturation | Harmful |

| H2 | 0-2 | 0-5 | 0-2 | 0-1 | Combustible |

| H2S | 100-7000 ppm | 0-1 | 0-8 | 0,5-3000 ppm | Corrosive |

| NH3 | 50-100 mg/m2 | Trace | Trace | Trace | Corrosive |

| CO | 0-1 | 0-1 | 0-1 | Trace | Combustible |

| N2 | 0-1 | 0-3 | 0-1 | 0-20 | Inert |

| 02 | 0-1 | 0-1 | 0-1 | 0-5 | Corrosive |

| Siloxanos | NR | 0-100 mg/m2 | NR | 0-50 mg/m2 | Abrasive |

| HCH | NR | Trace | NR | 10-4000 mg/m2 | Harmful |

Table 1

Although all types of biogas are suitable for biomethane production, biogas from controlled processes is of better quality for the purpose of transformation into a gas with similar properties to NG. This is due to the methane (CH4) concentration that can be achieved and the lower concentration of contaminants, such as O2. Table 1 shows the typical composition of biogas generated in accordance with waste types.

At present, a number of technologies are appearing on the market for the enrichment of biogas or its conversion into biomethane (high and constant NCV), which makes this gas a substance with great potential for application. These techniques include:

Chemical absorption: This is based on an acid-base reaction, for which purpose a selective reagent that minimises methane (CH4) loss is used. This technology operates at low pressures.

Scrubbing with pressurised water. This is based on the principle of the solubility of the gases in water, which depends on temperature and pressure. There are two technology types in this case: with water recirculation and without recirculation. These technologies operate at high pressures.

Adsorption techniques: Molecular sieves. Based on molecular attraction forces between the adsorbate and the adsorbent (Van der Waals forces), where a certain chemical reaction occurs and an important role is played by the ratio of molecular size to the pore size of the adsorbent. There are a number of different techniques in this category, the most common of which is based on pressure swing adsorption (PSA). This technology is characterised by operating at high pressures.

Cryogenic separation: Based on continuous compression, cooling and expansion (cold distillation) of the biogas. These operations enable the separation of the CO2 from the biogas, thereby increasing the methane (CH4) concentration of this gas. It is based on knowledge of the triple point of each component and the conditions at which this point can be reached (T & P). This technology operates at high pressure.

Membrane separation: Based on the principle of the permeability of the different components. Permeability is the capacity of a material to allow a flow to pass through it without altering its internal structure. Generally, hollow fibre type membranes are used. The process requires high pressures.

Table 2 shows the typical composition of natural gas, biogas and the enriched biogas (biomethane). In this case, the enriched biogas is achieved by means of scrubbing with pressurised water.

| Components | Natural Gas (%) | Biogas (%) | Biomethane (%) |

|---|---|---|---|

| CH4 | 86-93 | 50-75 | 89-98 |

| CO2 | 9,5-13 | 25-50 | 0,5-2 |

| Propane | 0,4 | 0 | 0 |

| Butane | 0,09 | 0 | 0 |

| H2S | 0 | 0-5000 ppm | 0 |

| NH3 | 0 | 0-500 ppm | 0 |

| VH 0 | 0 | 0,1-5 | 0 |

| Inert particles | 0 | > 5μm | 0,1 |

| N2 | 0,68 | 0-14 | 0-5 |

| Siloxanes | 0 | 0-100 mg/m | 0 |

| HCH | 0 | 0-4000 mg/m2 | 0 |

Table 2

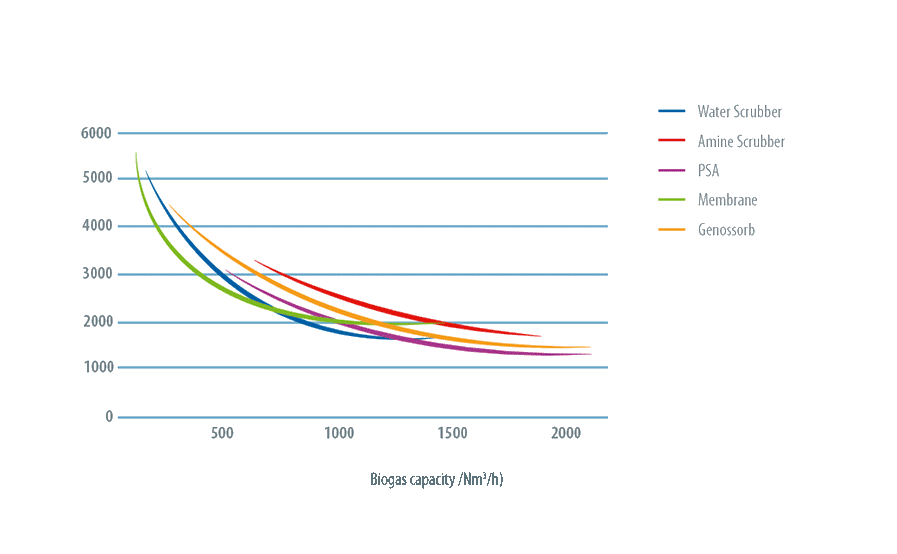

Figure 1 shows the behaviour of estimated cost of investment vs capacity to treat raw biogas for the different available biomethane production technologies.

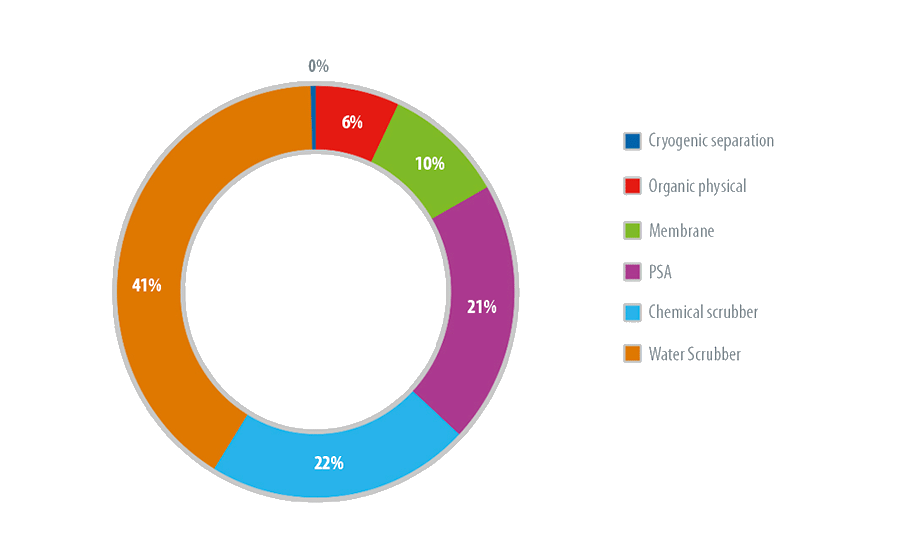

Figure 2 shows the current degree of application of the different technologies used to enrich biogas to achieve the quality of natural gas. According to the graph, three techniques are most commonly applied: Scrubbing with pressurised water, chemical scrubbing and pressure swing adsorption (PSA). Owing to the development of membrane features, the use of membrane separation is increasing in this sector.

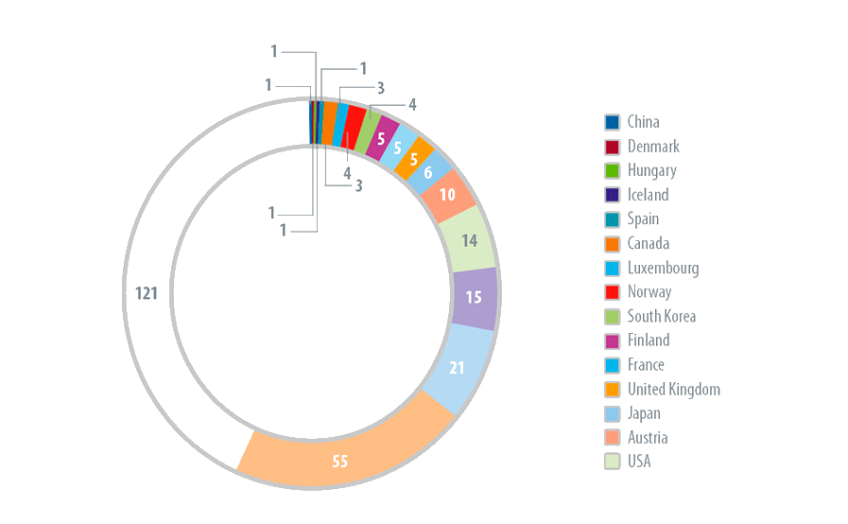

Figure 3 shows the application of the biogas enrichment techniques in different countries. The basic application is geared towards the production of biomethane for grid injection.

Biogas upgrading. From biogas to natural gas.

Biogas from different sources is a valuable material for the production of energy, chemical products and bio-fuels. Because it is a renewable energy, it is inexhaustible, clean and can be used in a self-administered manner, which enables production to be planned and adapted to consumption needs. The use of biogas causes less pollution and constitutes a viable alternative, given the noticeable depletion of fossil fuels, the prices of which are now increasing.

The current trend is to focus on the production of biogas as a substitute for natural gas, for grid injection or to power motorised vehicles.

Natural gas is found underground in the natural environment in “gas pockets” covered by impermeable layers which prevent it from being released into the atmosphere. It can also be found along with crude oil in oil wells or in exclusive natural gas fields. The main component of natural gas is always methane (CH4), which accounts for between 83% and 97% of the total volume of the mixture. Other gaseous hydrocarbosns that are always present in natural gas, though in smaller proportions, are ethan (C2H6), buthane (C4H10) and propane (C3H8). Finally, components of natural gas, other than hydrocarbons, normally include nitrogen, carbon dioxide, hydrogen sulphide, helium and argon.

Development in the field of biogas has reached the point where the trend is towards increasing focus on the use of biogas as a substitute for natural gas, through the production of biomethane. Different technologies are appearing on the market to achieve this conversion.