Manufacture of vacuum crystallization equipment

We manufacture industrial vacuum crystallizers for the treatment of industrial wastewater and waste concentration. We have an extensive experience in the design, manufacture and installation of crystallization equipment for zero liquid discharge (ZLD) projects. Each plant is designed to meet the specific requirements of the customer and maximize its efficiency.

At Condorchem Envitech we are specialists in vacuum crystallization for the treatment and reuse of high pollutant effluents and the concentration of raw materials or by-products.

Our DESALT® equipment provides a very high percentage of clean water to be discharged or reused, and a minimum solid concentrate to be sent for disposal or used as raw material or as a by-product.

Crystallization is a great technology for companies that are committed to zero liquid discharge and circular economy. This technology is particularly suitable for high salinity effluents (brines).

Types of crystallizers

Condorchem Envitech’s range of crystallizers for wastewater treatment includes the following industrial crystallizer equipment:

This industrial vacuum crystallizer is used for applications in which simultaneous concentration and drying in the same equipment is required: Crystallization of brines, concentration of spent working baths and concentration of extracts and fragrances.

The concentrated by-product can be extracted manually or with the help of a spindle (optional).

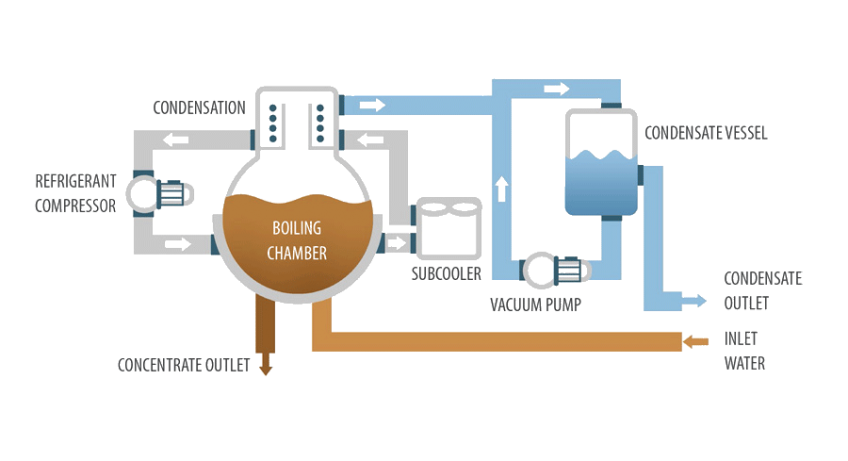

It is an industrial vacuum evaporator-crystallizer of horizontal construction that operates at low temperature and it is powered by electricity. This evaporative crystallizer design is operated by an electric heat pump, has a very compact structure and does not produce emissions or odors. It can be built in highly corrosion resistant materials if required.

It is designed to obtain solid, crystalline, paste or gelatine concentrates, as well as to recover raw materials present in wastewater.

Its capacity range is 250-1,000 L/day.

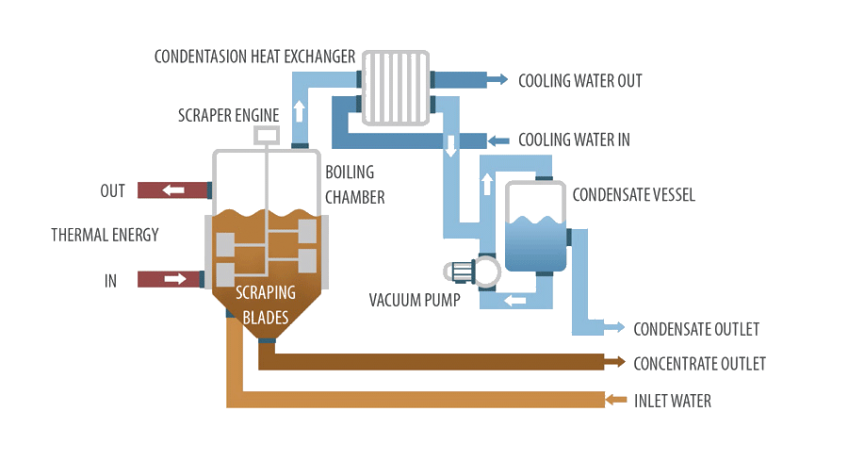

This industrial crystallizer is used for different applications, such as fouling liquids, brines, glues, inks and paints, for example.

It is a vacuum evaporator crystallizer of vertical construction with an internal scraper with blades. The heating is produced via steam or hot water. It can be manufactured in highly corrosion resistant materials if required.

This industrial crystallizer is designed for the concentration or crystallization of brines and concentrated fluids coming from an evaporator. Organic fluids can be concentrated into paste form. The equipment is especially recommended for treating fouling wastewater and high density aqueous solutions.

Its capacity range is 500-3,000 L/day.

Our industrial vacuum crystallizers

Advantages of vacuum crystallizers

Industrial vacuum crystallizers allow the complete removal of liquid from an effluent, transforming the paste into a dry solid, usually crystallized. Its function is based on heat application with the aim of evaporating the liquid until a consistent solid is obtained.

Crystallization is an essential step in most resources recovery processes, as it allows the recovery and concentration of raw materials and by-products, such as fertilizers, acids, metals, minerals, salts, oils, etc. Furthermore, it contributes to reduce the final weight of the waste and thus reduce its transportation and management costs.

These are some of the main advantages of installing a cristallyztion plant:

- Minimization of the waste volume to be managed

- Significant reduction in waste management costs

- Possibility of implementation of a zero discharge system

- Fulfillment of the current regulations on discharge of effluents

- Reduction of the need to store large volumes of waste

- Reduction in greenhouse gas emissions when transporting the waste

- Absence of reagents (except for antifoam in some cases)

Applications and ZLD

Crystallization has a key role in zero liquid discharge systems, in which liquid effluents are subject to a range of processes to obtain dry waste and pure water flow. While water is reused, the effluent is transformed into a small amount of dry solid that can be recycled in many cases.

These are some of the most common applications of industrial crystallizers.

- Treatment of effluents with a high contaminant load

- Useful when treated effluents cannot be discharged (implementation of a zero discharge system)

- Treatment of effluents when conventional techniques are not effective (as in the case of brines)

- Concentration of raw materials

- Maximum concentration of waste when external management costs are very high

By means of our DESALT® technology we are able to produce a solid concentrate that may be used as a raw material or a by-product. We offer two types of crystallizers: Desalt LT DRY and Desalt LT VR.

Introduction to vacuum crystallizers

Crystallization is a separation method in which the formation of a solid (crystal or precipitate) is produced from a homogeneous, liquid or gaseous phase. The solid formed can be very pure, so crystallization is also used industrially as a purification process.

The solution must be supersaturated before crystallization can occur. The Crystallization processes differ from one another in the method by which supersaturation is achieved. In general, it can be achieved in three different ways:

- Supersaturation produced by cooling the solution with negligible evaporation.

- Supersaturation produced by evaporation of the solvent with little cooling.

- Evaporation by a combination of cooling and evaporation in adiabatic evaporators (vacuum crystallizers).

The Crystallization process is not simple and the most important step is the formation of solid crystals in the liquid solution. The solution is concentrated and cooled until the concentration of the solute is higher than its solubility at that temperature, and the solute forms almost pure crystals.

Functioning/operation of industrial crystallizers

The operation of a crystallizer is very similar to that of a vacuum evaporator, except that it is designed to evaporate all the solvent and leave a very concentrated, pasty, gelatinous or crystalline product. There is usually a side opening so that it is easy to open and accessible for the manual extraction of the crystallized salts. At the end of the working cycle, the vacuum is released and the boiler contents are manually discharged with a scraper blade via one of the front doors.

Crystallizers can work well with a heat pump, steam or hot water.