Condorchem Envitech Offer

We design, manufacture and install falling film evaporators, which are a very efficient technology for the treatment of industrial wastewater, as they allow the separation of high quality water from an effluent containing a high concentration of pollutants.

Our falling film evaporators use thermal energy. However, when operating under vacuum conditions, the boiling temperature is reduced, which translates into a reduction of energy consumption. This low energy consumption, together with their effectiveness to manage polluted water, makes them a highly efficient technology to treat industrial wastewater.

It is a technology that provides excellent results in circular economy processes, as it offers the following advantages:

- Recovery and reuse of up to 98% of clean water.

- Recovery of resources, such as raw materials and by-products, which are present in wastewater.

- Reduction of energy consumption.

- Reduction of solid waste management costs thanks to the minimization of the volume of waste to be treated. The cost of the manager and transport is reduced.

Our falling film evaporators are comercialized under the ENVIDEST MVR FF series of equipment, with flow rates up to 2,500 L/h per modular unit.

Different models are available depending on their capacity:

- Envidest MVR FF 30-2500, from 30 L/h to 2500 L/h

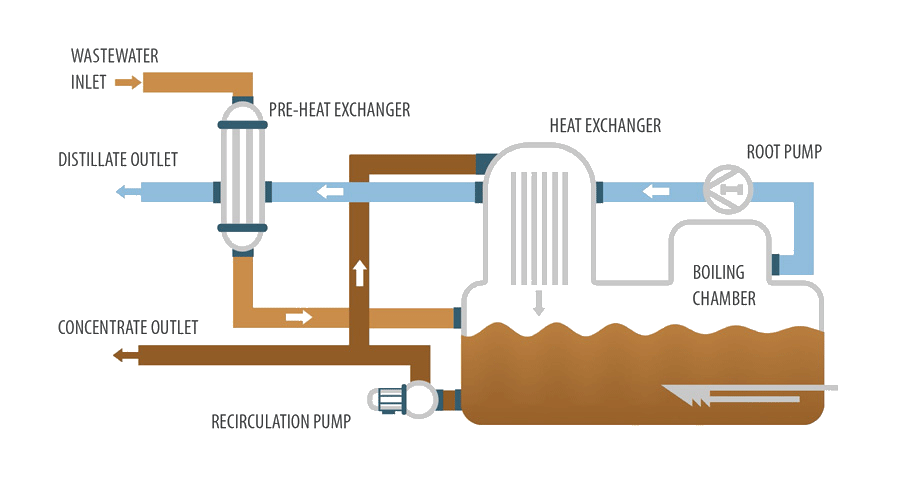

The equipment has vertical type boilers built in AISI 316-L with an integrated centrifugal separator and a pre-heat exchanger with counter flow plates to cool the distilled steam while at the same time preheating the incoming wastewater. They are equipped with a vacuum blower pump, a root type vapor compressor and a double-ended centrifugal pump with closed cooling system to produce the forced circulation of the fluid to be treated.

The falling film system produces a layer of fluid which slides on the inner surface of the exchanger providing instant evaporation; it reduces fouling of the heat exchanger and eliminates foaming. In addition, the concentrate is discharged with the same pump.

Falling film evaporators are suitable to treat wastewater with the following characteristics:

- Liquids that are too viscous for natural circulation

- Effluents where the retention time must be minimized

- When wastewater composition is sensitive to high temperatures

- When excess temperature is critical

- Effluents that require a limited temperature difference

Main features

- Flexible operation

- Simplicity of construction

- It can be build with materials that are resistant to corrossion to prevent scaling

- Handles liquids that increase in viscosity at higher concentrations because the liquid flows as a thin film over the surface of the heating tubes

- Vaporizes viscous materials more easily than natural circulating evaporation as vaporization occurs from a thin film

- It is used advantageously with thermal recompression with consequent energy savings

- Low energy requirements

- Low retention volume

Our falling film evaporators

Introduction to technology

Mechanical vapor compression and falling film evaporators are suitable for volumes of up to 4,000 L/h per modular unit.

These evaporators produce practically no foam, due to their high-performance separator. The internal division in the hot and cold zones reduces wear in the control and regulation equipment. The cleaning system integrated into the equipment is automatic, and is thus continuously available. All important process parameters are displayed on a touch screen. Its design, with large doors on both sides, facilitates its use and maintenance.

Vacuum evaporators can concentrate a waste effluent as many times as necessary, resulting in zero discharge if required. Its operation is simple and its efficiency is high. Evaporation under vacuum can treat effluents of a complex nature, which more conventional techniques cannot effectively treat.

In this type of evaporators, the effluent to be treated is fed continuously, using a special uniform distribution system, which allows the formation of a thin film on the circumference of the evaporator tubes. The film flows downward with the concentrate and reaches the bottom of the equipment to a boiler, where the steam goes to a condenser and the distillate flows out of the condenser.

Similarly, the non-evaporated liquid that flows through the tubes of the equipment is continuously concentrated by evaporation. The concentrate and the distillate are continuously discharged through a pump.

Falling film evaporators operate with low temperature variations and short residence times, which makes them suitable for products that are sensitive to high temperatures.

The design of the vapor / liquid separator at the bottom of the tube plate needs to consider the properties of the wastewater that it's being treated. The ratio of the distilled effluent versus the feed rate is critical to obtain a correct falling film, otherwise the liquid flow could produce moisture inside the tubes, which could cause scaling and subject the tubes to possible fouling from the degraded product. That's why the liquid is only heated in the exchanger and no boiling occurs inside the tubes; This reduces the risk of scaling inside the hot tube walls.

Functioning/operation of falling film evaporators

The operation of the mechanical vapor compression vacuum evaporators is based on the recovery of the condensation heat from the distillate as a source of heat to evaporate the feed.

In these systems, the process starts with the external energy supply to the evaporator to start the falling film evaporation process. The operation of the mechanical vapor compression vacuum evaporators is based on the recovery of the condensation heat from the distillate as a source of heat to evaporate the feed. The steam produced is extracted and compressed by a volumetric compressor with the intention of increasing its temperature. This superheated steam is then returned to the evaporator as a heating fluid. Once the cycle has begun, no more external heat input is required, as the mechanical compression of the steam provides enough heat to maintain the evaporation of the liquid. Upon passing through the exchanger of the evaporator itself, this compressed, and therefore superheated, vapor has two effects: (1) it heats the liquid to be evaporated and (2) it condenses, thereby reducing the need for a refrigeration fluid.

The main advantage of mechanical vapor compression vacuum evaporators lies in the fact that the energy consumption of the volumetric compressor is lower than the cost of producing steam for multi-effect evaporation systems. However, the volume to be evaporated must be high enough so that the saving generated compensates for the investment in the volumetric compressor.

Falling film mechanical vapor compression evaporators consist of a housing and tubes. The product circulates through the interior of the tubes and the steam through the housing, heating its outer walls.

The effluent enters at the top and slides uniformly through the tubes by gravity in the form of a thin layer which is heated by contact with the inner wall.

This equipment can also work with low temperature differences due to the high coefficients of thermal transfer obtained.