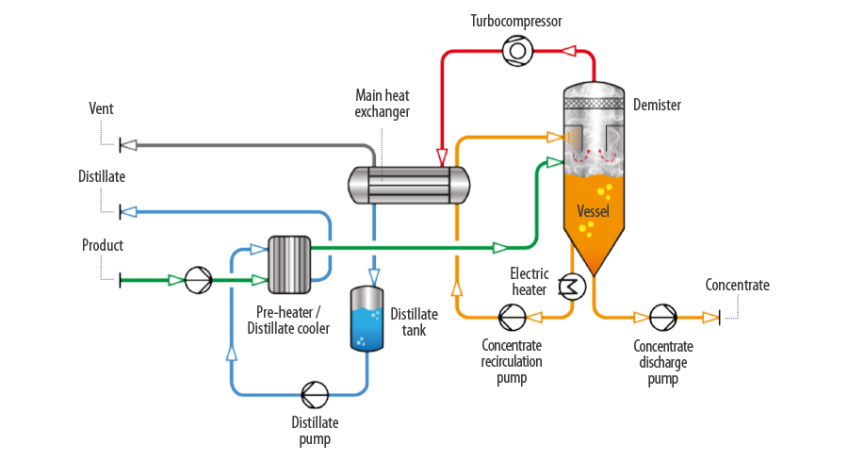

The ENVIDEST MVR FC TF series vacuum evaporator is designed to treat aqueous-based streams with a low contaminant load, standing out for its energy efficiency, based on Mechanical Vapor Recompression (MVR) technology.

The recirculation pump, operating at high speed, plays a crucial role in preventing the formation of scale in the main shell-and-tube heat exchanger.

The operation of the equipment is fully automatic - 24 hours a day.

Main features

- Technology: Mechanical Vapor Recompression (MVR)

- Evaporation: Forced Circulation (FC)

- Single/Multi-Effect: Single-Effect

- Vacuum: ≈ 750 mbar

- Evaporation Temperature: ≈ 90–94 °C

- Evaporation Vessel: Conical bottom

- Droplet Separator: Mesh Demister

- Heat Exchanger for Heating: Shell and tube

- Vacuum System: Turbocompressor

- Control Unit*: PLC Siemens with HMI touch screen

- Protection: IP54

- Electricity Supply**: 400 V III + PE 50 Hz

- Standard Manufacturing Material: 1.4401/1.4404 (AISI 316/AISI 316L)

- Special Anti-corrosion Manufacturing Material***: 1.4410 (Superduplex 2507) / Ti

* Different PLC manufacturer available on request

** Different voltage supply available on request

Diagram

Technical specs

| Parameter | Unit | 1000 | 2000 | 3000 | 4000 |

|---|---|---|---|---|---|

| Capacity* | L/h | 1042 | 2083 | 3125 | 4166 |

| Electricity Consumption** | kWh/m³ | 35 | 35 | 35 | 35 |

| Length | mm | 8500 | 9450 | 12450 | 12450 |

| Width | mm | 2350 | 2350 | 2450 | 2450 |

| Height | mm | 5350 | 5480 | 5480 | 5480 |

* Data refer to clean water when working continuously in standard conditions (T = 20 °C, P = 1013 mbar).

** Electricity consumption expressed in kWh per m³ of distillate produced.