The ENVIDEST MVR FC evaporators represent a new concept of evaporators with forced circulation by means of mechanical vapour compression in order to produce 250-2,000 L / h of distillate.

Preheating system of the water to be treated for equipment start-up (for two hours) using electrical resistors installed inside the boiler or by vapour supply provided by the client.

Our evaporators ENVIDEST MVR FC

Main features

- Vertical boiler, manufactured with the material AISI 316 L.

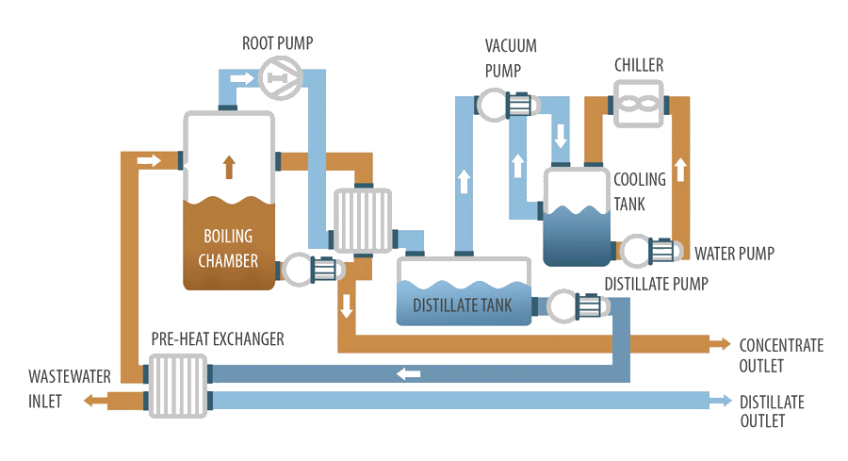

- Large capacity for continuous operation of the machine.apour compression system using a Root pump.

- Vacuum formed by a liquid ring pump. A system for cooling the pump using a chiller installed outside the frame.

- A system for recirculating concentrated water using a centrifugal pump.

- A plate exchanger for exchanging heat between the fluid to be treated and the vapour produced, causing the condensation of the latter (distillate).

- Manufactured with AISI 316 L.

- Pre-plate exchanger to pre-heat the water to be treated. Exchange between the water to be treated and the distillate obtained.

- Condensation tank manufactured with AISI 316 L.

- Automatic control by weight, pressure and temperature.

- Load cells, for control by weight.

- Scaled level sensor for continuous control of the process.

- Manometer for controlling the vacuum and the operation of the vacuum pump.

- Machine started using electrical resistance or vapour feed.

- Pipes manufactured with AISI 316 L.

- Cleaning in place system for the inside of the evaporator, thus guaranteeing its continuous availability.

- Control cabinet built into machine with protection and operational control equipment.

- It has PLC, analogue modules for instrumentation and touch HMI with a screen.

Optional features

- Machine with panelling to minimise the noise and optimise the performance of the machine at thermal level.

- It is possible to feed the machine, the parts in contact with the liquid, with a special material that is resistant to corrosion (SAF 2507 or TITANIUM) (effluent with a high chloride or fluoride, etc., content).

- Distance management MODEM.

- Other electrical supplies are available.

Diagram

Technical specs

| Units | 250 | 500 | 750 | 1000 | 1500 | 2000 | |

|---|---|---|---|---|---|---|---|

| Feed Inlet | I/d | 5.000 | 10.000 | 15.000 | 20.000 | 30.000 | 40.000 |

| Nominal Capacity | I/h | 250 | 500 | 750 | 1000 | 1500 | 2000 |

| Energy Consumption | W/I | 52 | 52 | 48 | 48 | 48 | 48 |

| Dimensions (LxPxH) | cm | 320x190x290 | 350x210x290 | 400x220x325 | 450x220x340 | 470x220x350 | 490x220x350 |