Condorchem Envitech Offer

Condorchem Envitech has a laboratory for the analysis and characterization of industrial wastewater, as well as for the simulation and validation of industrial water treatment plants.

Our industrial effluent analysis and characterization service is essential to ensure the best results when designing an industrial wastewater treatment plant, as it allows us to obtain the following information:

- Analysis of the effluent to identify all existing contaminants and their composition.

- Testing and simulation of the proposed solution at the laboratory scale before its implementation at an industrial scale.

Our Laboratory

Analysis and Characterization of Wastewater

Our laboratory has various equipment for simulating a wide range of processes: physicochemical, ultrafiltration (UF), nanofiltration (NF), reverse osmosis (RO), evaporation, crystallization, stripping, adsorption with activated carbon, as well as numerous analytical methods.

The goal is to determine the most efficient and suitable treatment process for each industrial effluent.

During laboratory studies, the conditions of the industrial equipment, which will later be installed at the client's facilities, are simulated. This study has the following main objectives:

- Validate the appropriate technological choice.

- Optimize the operating conditions of the units.

- Determine the appropriate pre-treatment and post-treatment for each effluent.

In this way, we ensure that the process and technologies are the ones that will offer the best results to the client. To achieve this, the tasks to be performed include:

- Study of different technologies for the recovery, management, or reduction of wastewater or emissions to be treated.

- Conducting laboratory tests or atmospheric measurements representing the treatment plant to verify design data and ensure the feasibility of the proposed solution.

- Conceptual design of the optimal treatment system using technologies supplied by Condorchem (Technologies for water, air, or waste treatment).

- Conclusions with process diagrams of the system and return on investment study.

- Design of industrial pilot tests (if required).

- Technical and economic proposal for the supply (design and manufacturing) of industrial equipment.

A typical protocol for pilot testing in our laboratory includes the phases of experimental study and conceptual engineering, divided into the following stages:

| Process | Description | Services |

| Phase 1 | Experimental Study |

|

| Phase 2 | Conceptual Engineering Study |

|

| Phase 3 | Basic, Detailed Engineering, and Equipment Manufacturing |

|

| Phase 4 | Installation and Commissioning |

|

| Phase 5 | After-Sales Service |

|

Results of the analysis and characterization

These are some of the most relevant parameters that can be analyzed in our laboratory tests:

| Parameters | Effluent | Distillate |

| Appearance | X | X |

| Color | X | X |

| Odor | X | X |

| Density | X | X |

| pH | X | X |

| Conductivity | X | X |

| Chemical Oxygen Demand (COD) | X | X |

| Cations | X | X |

| Anions | X | X |

| Total Organic Carbon (TOC) | - | - |

Other parameters that we can obtain:

- Humidity

- Dry residue

- Hardness

- Total Organic Carbon (TOC)

- Turbidity

The results obtained in the tests are included in a laboratory report sent to clients via email. This report includes the parameters obtained from both the water to be treated and the distilled water obtained, the concentration capacity of the wastewater, chemical consumption (if necessary), and our conclusions regarding the best treatment process.

Additionally, if the client requests it, a sample of the distilled water obtained and a sample of the final residue are provided.

To perform these analyses and studies, it is necessary for the client to provide us with two liters of a representative sample of the wastewater to be treated.

Example of an Analysis and Simulation to Achieve Zero Discharge

Concentration technologies such as evaporation and crystallization are the most efficient when aiming to achieve zero discharge. In this practical case, we outline the steps to obtain a solution for zero discharge from a sample provided to our laboratory by a client.

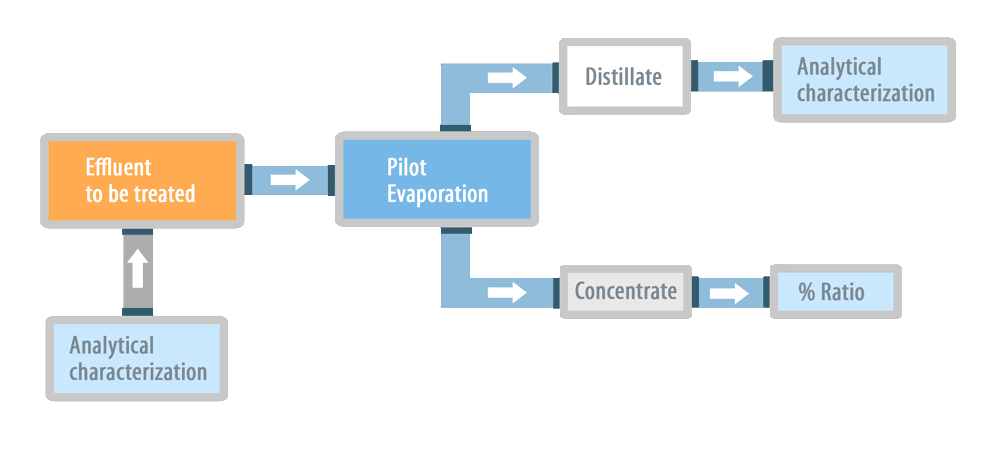

To determine the concentration capacity of the waters to be treated and the quality parameters of both the incoming water and the distilled water obtained, we propose conducting the following laboratory tests:

- Determination of Basic Water Parameters.

- Water to be treated: pH, conductivity, COD (Chemical Oxygen Demand), SS (Suspended Solids), ammonium nitrogen, and chlorides.

- Distilled water obtained: pH, conductivity, COD, ammonium nitrogen.

- Evaporation Test with the Water to Be Treated:

- Depending on the parameters of the water to be treated, analyze the need to install a pretreatment system for the water before evaporation. This may involve adjusting parameters through chemical dosing, filtration requirements, etc.

- Depending on the parameters of the distillate, assess the need to install a post-treatment system to meet discharge limits.

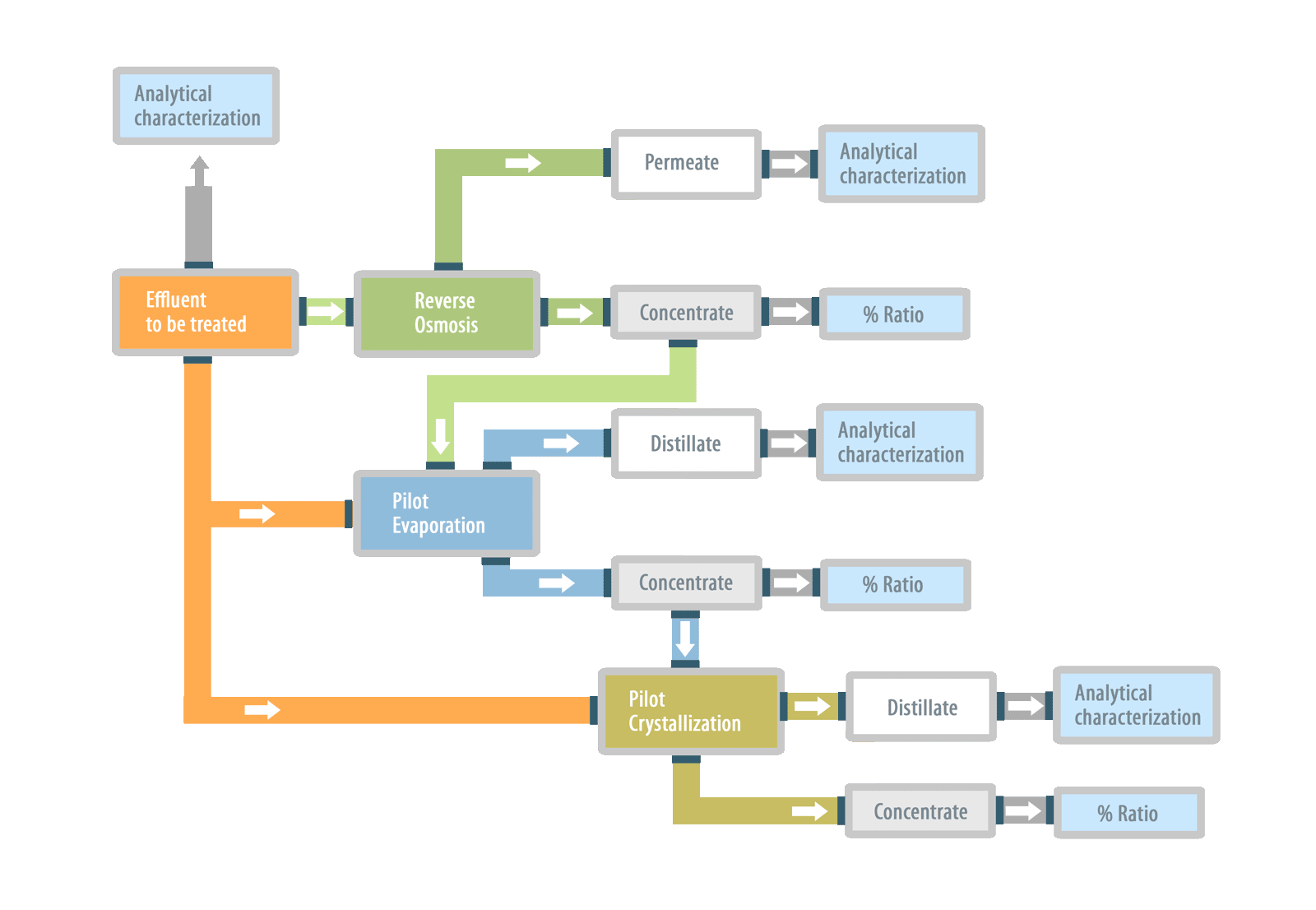

The following diagram illustrates the steps to characterize an industrial effluent, as well as to conduct tests and simulations using different pilot plants. This process is repeated until the most efficient solution for the client's needs is found.

Analysis Equipment

Our laboratory has the necessary equipment to carry out a detailed analysis and precise characterization of any industrial effluent.

The available equipment is as follows:

| Equipment | Brand | Model | Year of Purchase | Description |

| Stirrer | IKA | TOPOLIN | 2011 | Mini magnetic stirrer |

| Stirrer | LLG | UNISTIRRER 2 | 2018 | Compact magnetic stirrer for volumes up to 1000 ml. Adjustable speed from 0 to 2000 rpm. Plate diameter 120 mm. |

| Stirrer | MAGNA | AN02 | 2002 | Magnetic stirrer |

| Stirrer with Heating Plate | SELECTA | 2002 | Magnetic stirrer with heating plate | |

| Stirrer with Heating Plate | LLG | UNISTIRRER 3 | 2018 | Magnetic stirrer with LED screen to control all parameters, integrated temperature control with PT-1000 sensor |

| Propeller Stirrer | IKA | Ministar 40C | 2018 | Propeller stirrer, reaches 1000 rpm. Temperature measurement. Viscosities up to 30,000 mPas and volumes up to 25 l. Continuous speed regulation between 0/30 and 1000 rpm |

| Orbital Shaker | SELECTA | AG 200 A | 2016 | With non-slip rubber platform 26 cm wide and 22 cm deep, with 3 rubber-coated holding bars for all types of beakers, Erlenmeyers, flasks, etc. |

| Freezer | CARREFOUR | 2011 | Freezer | |

| Safety Cabinet | EXACT | EFO06 | 2017 | For safe storage of flammable liquids with 90-minute fire resistance, according to EN 14470-1. Automatic door closure in case of fire |

| Balance | GRAM | SERIE BH BH-300 | 2005 | Capacity: 300 g. Sensitivity: 0.01 g. Plate dimensions: 116 mm. diameter. Operating temperature: 0º-40ºC |

| Balance | BLAUSCAL | AC5000 | 2007 | Weighing range (max.): 500 g. Reading accuracy: 0.1 g. Plate dimensions (mm): Ø 116 |

| Balance | OHAUS | PIONEER PA213 | 2015 | Resolution 1 mg., capacity 210 g., stainless steel plate Ø 120 mm. |

| Heating Bath | BUCHI | B305 | 2019 | For flasks up to 5 liters and 220ºC |

| Heating Bath | BUCHI | B491 | 2007 | For flasks up to 5 liters and 180ºC |

| Immersion Thermostat Recirculating Bath | OVAN | 200º Bath Ultra | 2018 | Temperature controlled with internal Pt100 probe. Backlit digital LCD screen with indication of selected and actual temperature value. Homogenization pump with a capacity of 6 liters/minute. (max pressure: 200mbar). Temperature range: Tªamb+5 – 200. Power: 2000 W. Dimensions (mm): 360x330x450 |

| Peristaltic Pump | SEKO | PR4 | 2010 | Flow rate 4 l/h |

| Vacuum Pump | BUCHI | V300 | 2019 | Polytetrafluoroethylene membrane vacuum pump resistant to chemicals. Flow rate of 1.8 m3/h and a final vacuum of 5 mbar. Can be combined with Rotavapor® R-300. |

| Vacuum Pump | BUCHI | V700 | 2007 | Vacuum pump resistant to chemicals. Flow rate of 1.8 m3/h |

| Vacuum Pump | KNF | LABOPORT N86KN18 | 2006 | Low-flow pump. Diaphragm pump and compressors for slightly corrosive vapors and gases. Flow rate l/min 6, Final vacuum mbar 100, Pressure bar 2.4. |

| Vacuum Pump | OPTIC MYMEN SYSTEM | GM-0.50 | 2013 | Vacuum 200 mbar |

| Vacuum Pump | DINKO | D-95 | 2016 | Vacuum mbar: 169. Pressure Bar: 2. Flow rate L/min: 6. Dimensions in cm: 24 x 27 x 10. Kg: 2.8 |

| Vacuum Pump | BUCHI | V100 | 2018 | Suction capacity (DIN 28432) 1.5 m3/h* Number of steps (heads) 2 (2) Final vacuum (absolute) 10 mbar (± 2 mbar) |

| Fume Hood | INDELAB | 2002 | Extractor hood with charcoal filter. 220 W | |

| Centrifuge | SELECTA | MIXTASEL | 2015 | Maximum speed of 4000 rpm. Includes oscillating rotor for 100 mL tubes. Timer up to 60 min. |

| Centrifuge | AIRESA | DIDACEN II | 2006 | Maximum speed of 3600 rpm. 230V |

| Chiller | BUCHI | F100 | 2016 | Maintains temperature at 10ºC |

| Chiller | BUCHI | F100 | 2018 | Maintains temperature at 10ºC |

| Conductivity Meter | CRISON | BASIC+30 | 2008 | Benchtop conductivity meter. Measures from 0.01 μS to 199 Ms |

| Portable Conductivity Meter | HACH | SENSION +EC5 | 2020 | With cell 5060 Conductivity measurement range: 1 μS/cm - 200 mS/cm (probe range) Temperature measurement range: -20.0 - 150.0 °C Salinity measurement range: 5.85 - 311 g/L TDS measurement range: 0 mg/L - 500 g/L |

| Anion Ion Chromatography | METROHM | IC883 BASIC | 2016 | AUTOMATIC ION CHROMATOGRAPHY SYSTEM. Complete system configured to determine anions and cations without column change. MagIC Net Professional 3.1 Software. IC anions SUPP 5 Column, 250mm |

| Cation Ion Chromatography | METROHM | IC883 BASIC | 2016 | AUTOMATIC ION CHROMATOGRAPHY SYSTEM. Complete system configured to determine anions and cations without column change. MagIC Net Professional 3.1 Software. IC cations C6 250/4.0 Column |

| BOD Analyzer | AQUALYTIC | OXIDIRECT | 2006 | Determination of BOD by measuring the pressure difference in the closed system (respirometric determination of BOD). Requires inductive stirring system in the thermostatized cabinet. |

| Air Diffusers | - | - | - | Air diffuser 1: 550 l/h. Air diffuser 2: 4 l/min |

| Filtration Equipment | KOCH | KMS Laboratory Cell CF-1 | 2018 | Membrane filtration equipment. Microfiltration, Ultrafiltration, Nanofiltration, and Reverse Osmosis |

| Spectrophotometer | HACH | DR3900 | 2018 | Visible spectrophotometer for water analysis. Spectral range 320-1100 nm. |

| Spectrophotometer | HACH | ODYSSEY 2500 | 2002 | Wavelength range 365 to 880 nm. Concentric optical system for multi-channel spectroscopy. Photometric range ±0.001 to 3.2 Abs |

| Stove | MEMMERT | UNB100 | 2006 | Oven with time and temperature controller. Maximum temperature: 220ºC |

| Photometer | MN | PF11 | 2000 | Single-beam filter photometer. Rotating filter holder with 6 colored glass filters, manual filter selection. Wavelengths 380 / 405 / 470 / 520 / 605 / 720 nm. Light source: Tungsten lamp |

| Power Supply | GRELCO | GVD310 | - | Output voltage: 0-30Vdc. Output current: 0-10A. Power 300w |

| Ozone Generator | OXITRES | MOD120 | - | Generates 120 mg/h of ozone |

| ICP/OES | SPECTRO | GENESIS SOP | 2016 | Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES). Determination of multiple elements. Optical ICP plasma. ARGON gas required |

| Heating Mantle | LAB HEAT | KM-M | - | Capacity 500 ml. Maximum temperature 450ºC |

| Moisture Analyzer | OHAUS | MB25 | 2018 | Maximum capacity 110 g. Plate size 90 mm. Minimum reading of 0.005 g/0.05%. Halogen heating |

| Refrigerator with Freezer | ELEGANCE | ETT-140 | - | Maximum refrigerator volume: 98 l. Maximum freezer volume: 10 l. Energy efficiency rating: A+ |

| pH Meter | CRISON | GLP22 | 2008 | Benchtop pH meter. Measures pH and redox. |

| Reactor | HACH | DRB200 | 2013 | Measures two temperatures (105ºC and 148ºC). Heating Rate: 20 to 150 ºC in 10 minutes. Number of cuvettes: 15 vials x 16 mm (single block) |

| Reactor | HACH | DRB100 | 2004 | Measures two temperatures (105ºC and 148ºC). 2 independent blocks |

| Rotary Evaporator | BUCHI | R300 | 2019 | Laboratory rotary evaporation applications. Dimensions (WxDxH) with glass apparatus V 607 x 429 x 947 mm. Rotational speed range 10 – 280 rpm. Maximum flask content 3 kg |

| Rotary Evaporator | BUCHI | R215 | 2007 | Laboratory rotary evaporation applications. Dimensions (W x H x D) 550 x 575 x 415 mm. Rotational speed range: 20 - 280 rpm. Maximum flask content 3 kg |

| Turbidity Meter | AQUALYTIC | PC COMPACT | 2006 | 4 measuring ranges from 0.2 to 2000 FNU. Measurement with infrared light at an angle of 90°. Measurements of colored liquids |

| Viscometer | BROOKFIELD | DV-E-VISCOSIMETER RV | 2015 | Measures fluid viscosity at specified shear rates. The DVE operates by rotating a spindle (immersed in the test fluid) through a calibrated spring. Speeds from 0.3 to 100 rpm. Operating environment: 0 °C to 40 °C. Viscosity accuracy: ± 1.0% |

| Sand Bath | SELECTA | COMBIPLAC | - | Electronic regulation of heating power. Indeformable steel heating plate. Bath container made of indeformable stainless steel AISI 310. |

| Vacuum Sealer | LADY VACUUM |