Sections

Introduction

The dairy industry is a sector whose main raw material is milk from animals (generally cows, goats, and sheep).

Milk is one of the basic foods of humanity. The by-products generated by this industry are known as dairy products and include a wide range of products, from fermented products like yogurt and cheese to non-fermented products like butter and ice cream.

Dairy industries that process liquid milk and products with a short shelf life, such as yogurts, creams, and soft cheeses, tend to be located on the outskirts of urban centers close to consumer markets.

Plants that produce longer shelf life products like butter, powdered milk, cheese, and whey powder tend to be located in rural areas close to milk production.

Most large-volume processing plants specialize in a limited range of products. However, large production plants with a wide range of products are still common in Eastern Europe, a vestige of the old centralized conception driven by market supply under communist governments.

In developing countries, it is common to find the production of these dairy products taking place on the same dairy farms.

Around 90% of sheep and goat milk production is destined for the processing industry, while the remaining 10% is used for artisanal cheese production.

It takes between 9 and 10 kg of cow’s milk to produce 1 kg of cheese, but only 8-9 kg of goat’s milk and just 5 kg of sheep’s milk are needed.

Scope of Application

Milk is an essential food in the daily human diet as it is rich in nutrients and a source of high-quality proteins.

It contains components with scientifically proven beneficial properties for the immune, cardiovascular, and digestive systems, and is also the main dietary source of calcium, not only because of its high calcium content, but also because of its high bioavailability due to other included components.

However, in recent years, messages without much scientific basis have started circulating claiming that milk consumption can be harmful to health.

In economic terms, it is estimated that more than 750 million people worldwide are involved in milk production. The dairy sector provides more employment per unit of milk production in developing countries than in developed countries.

This is mainly due to the fact that developed countries have production systems with higher use of technology and lower use of labor.

In developing countries, small-scale market-oriented milk production generates employment on farms, increases agricultural income, and creates jobs outside the farm in milk collection, marketing, and processing.

In many developing countries, milk production offers small farmers higher profits than crop production and generates more employment opportunities than other value chains in the food sector.

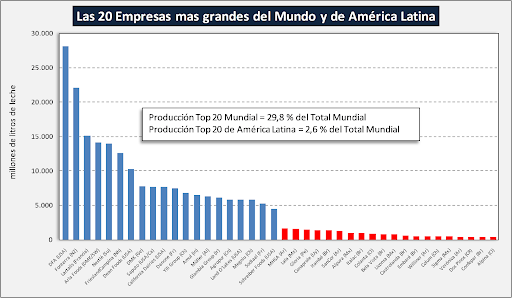

Currently, there are many important companies dedicated to the dairy sector, among which the ones shown in this graph stand out:

The following tables show the world’s largest producers and consumers.

Producers:

| BLOCKS/COUNTRIES | 2018 billion kg of milk | Variation 2017-2018 |

| EUROPEAN UNION 28 | 166.7 | 0.8% |

| USA | 98.7 | 1.0% |

| INDIA | 90.2 | 7.98% |

| BRAZIL | 34.7 | 0.5% |

| CHINA | 30.8 | 1.2% |

| RUSSIA | 30.6 | 1.4% |

| NEW ZEALAND | 22.2 | 3.0% |

| TURKEY | 20.0 | 6.8% |

| PAKISTAN | 17.4 | 3.8% |

| MEXICO | 12.4 | 2.0% |

| Top 10: 74.4% of total world production | ||

Per capita consumption:

| Selected Countries/Blocks 2018 | Milk | Butter | Cheese |

| France | 45.3 | 8.4 | 26.5 |

| Germany | 51.4 | 5.8 | 24.1 |

| Lithuania | 40.9 | 4.1 | 20.8 |

| European Union | 59.4 | 3.9 | 18.9 |

| Australia | 101.8 | 3.2 | 14.0 |

| United States | 65.3 | 2.6 | 17.3 |

| New Zealand | 105.4 | 5.9 | 10.1 |

| Belarus | 69.7 | 3.0 | 13.5 |

| Ireland | 114.7 | 2.4 | 6.8 |

| Argentina | 35.6 | 0.6 | 12.9 |

| Uruguay | 62.4 | 1.6 | 9.5 |

| Chile | 25.5 | 1.7 | 10.6 |

| Russia | 33.7 | 2.1 | 5.6 |

| Mexico | 33.1 | 0.7 | 4.3 |

| Brazil | 39.3 | 0.4 | 3.7 |

| Japan | 30.9 | 0.6 | 2.5 |

| South Africa | 28.3 | 0.5 | 1.9 |

| China | 21.4 | 0.1 | 0.1 |

| Zimbabwe | 2.7 | 0.0 | 0.6 |

EFFLUENT GENERATION

Wastewater generation is the most significant environmental aspect of the dairy industry, both due to the high volumes generated and the associated pollutant load.

Most of the water used ultimately becomes effluent, as there is no water input to the final product. Therefore, the wastewater generated in a manufacturing process will be the result of subtracting the lost water due to evaporation from the total consumption.

In general, between 80-95% of the total water consumed becomes part of the final effluent, except for exceptions in the production of powdered milk, etc. The main partial streams that contribute the most in terms of volume and/or pollutant load to the final effluent come from:

- Equipment and facility cleaning, CIP cleaning of lines, etc.

- Rejects from ultrafiltration systems or osmosis systems in the processing of certain derivatives.

- Cleaning of raw material transport trucks.

Concentrations may vary from one facility to another, and in certain cases, they may have significantly different values than those mentioned above. The causes of variability in the concentration of effluent parameters are multiple, with the following being the most notable:

- The degree of optimization of water consumption,

- Cleaning procedures and chemicals used, CIP cleaning.

- The technology used in water-consuming operations.

- Changes in production as a result of variations in the products to be manufactured.

These waters usually have the particularity of high fat and high nitrogen content (hence the need for nitrification/denitrification processes) and high phosphorus content. In addition to the well-known problems of high COD.

Like most companies in the agri-food sector, dairy industries consume large amounts of water daily in their processes, especially to maintain the required hygienic and sanitary conditions.

Depending on the type of facility, the cleaning and usage system, the total amount of water consumed in the process can exceed several times the volume of milk processed.

This consumption is usually between 1.3-3.2 liters of water per kg of received milk, reaching as high as 10 liters of water per kg of received milk.

However, it is possible to optimize this consumption to values of 0.8-1.0 liters of water per kg of received milk using advanced equipment and proper operation.

As indicated in the table below, the highest water consumption occurs in auxiliary operations, particularly in cleaning and disinfection, where between 25-40% of the total water is used.

Qualitative assessment of water consumption in the dairy industry

| PRODUCTION PROCESS | LEVEL OF CONSUMPTION | OPERATIONS WITH HIGHEST WATER CONSUMPTION | REMARKS |

| Milk | Low | Thermal treatment Packaging | |

| Cream and butter | Low | Pasteurization of cream Churning-Kneading | Washing of the churn before kneading |

| Yogurt | Low | Mainly in auxiliary operations | |

| Cheese | Medium | Salting | Salting with brine |

| Auxiliary operations | High | Cleaning and disinfection Steam generation Cooling | These operations account for the highest water consumption |

Typical composition of wastewater from dairy industries

In general, the liquid effluents from a dairy industry have the following characteristics:

- High organic matter content due to the presence of milk components. The average COD of dairy industry wastewater is between 1,000-6,000 mg O2/l.

- Presence of oils and fats due to the fat in milk and other dairy products, such as in the washing water of the churn.

- Elevated levels of nitrogen and phosphorus, mainly due to cleaning and disinfection products.

- Significant variations in pH, with the discharge of acidic and alkaline solutions. Mainly from cleaning operations, pH values can vary between 2-11.

- High conductivity (especially in cheese-producing companies due to the discharge of sodium chloride from cheese salting).

- Temperature variations (considering cooling water).

- Losses of milk, which can range from 0.5-2.5% of the amount of received milk or up to 3-4% in the most unfavorable cases, are a significant contribution to the pollutant load of the final effluent. Approximately, one liter of whole milk is equivalent to a BOD5 of 110,000 mg O2/l and a COD of 210,000 mg O2/l.

Dairy industries can be single-product or multi-product. The following table shows the typical concentrations of each type of effluent depending on the product being manufactured:

| PARAMETER | MILK | CHEESE | DAIRY DERIVATIVES | ICE CREAM |

| pH | 8.5 | 6.9 | 8.5 | 8 |

| COD (mg/l) | 1775 | 4500 | 4000 | 925 |

| Suspended Solids (mg/l) | 435 | 850 | 825 | 425 |

| Phosphorus (mg/l) | 20 | 35 | 6.25 | 5.5 |

| Nitrogen (mg/l) | 65 | 100 | 100 | 75 |

| Conductivity (S/cm) | 1650 | 3150 | 1250 | 1200 |

| Chlorides (mg/l) | 140 | 220 | 100 | 135 |

| Nitrates (mg/l) | 50 | 105 | 90 | 75 |

| Oils and Fats (mg/l) | 105 | 365 | 110 | 25 |

| Detergents (mg/l) | 3.5 | 7 | 7.5 | 6 |

EFFLUENT TREATMENT

A wastewater treatment plant for dairy effluents needs to be designed primarily to reduce pollutant levels of parameters such as BOD5, oils and fats, suspended solids, and to correct the pH of the effluent.

Despite the variability in discharge parameters, basic control and pretreatment systems can be considered that adapt to the general characteristics of the effluents generated and can serve as guidance for companies to develop more specific and suitable systems for their effluents.

In general, the treatment of these wastewater can be carried out through biological treatment, requiring prior separation of suspended solids and fats and oils.

In the case of wastewater from cheese production, the removal of phosphorus may also be necessary. On the other hand, given the extremely high COD and conductivity of whey, the first control measure is to fully recover the whey residues and prevent them from mixing with the rest of the wastewater.

Wastewater treatment systems must be those that guarantee compliance with the limits established by legislation depending on the point where the company discharges (if the discharge is made to a public watercourse, the limits are more restrictive than if it is discharged to a wastewater treatment plant).

A typical effluent treatment plant in this sector consists of:

- Pretreatment, including screening and homogenization

- Physicochemical treatment

- Biological treatment

- Sludge drying

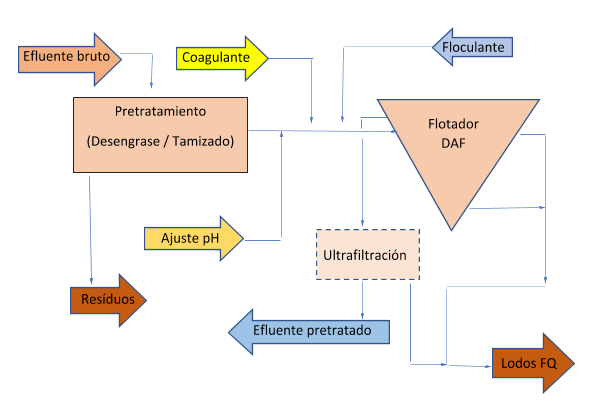

Pretreatment

Pretreatment can be physical or physicochemical, depending on the concentrations of those contaminants that inhibit the biological process.

A basic (but not sufficient) control and pretreatment system that all companies in this sector should have, and that in some cases will be sufficient for them to discharge within the established limits, should consist of the following elements: Aeration regulation system-homogenization. Grease and oil separator. A tank or pond of sufficient size to ensure continuous flow supply to the subsequent grease separation system.

This tank also allows for the initial equalization of the load peaks and volumes of different wastewater flows. Aeration of the tank is advisable to prevent unwanted anaerobic acid fermentations.

A grease and solids separator by flotation. Depending on the characteristics of the effluent, the addition of coagulating agents and pH control may be necessary to ensure good separation performance.

At the head of the installation, screens with different openings are usually installed (a coarse screen with openings of about 20-30 mm, followed by a fine screen with openings of about 5-10 mm; after grease separation and before reaching the physicochemical treatment, circular or curved screens with openings of about 3-5 mm are usually used to ensure proper separation of settleable solids or large-sized solids.

The presence of these solids causes significant problems, especially in the pressurization tank of the flotation system in the subsequent physicochemical treatment, as they accumulate inside, causing fouling, clogging, and even decomposition of COD; if flotation does not work properly and excessive oils and fats reach the biological system, the treatment loses effectiveness as bacteria have more difficulty reaching their food source.

Physicochemical Treatment:

It usually consists of a dissolved air flotation (DAF) system, which receives the dosing of coagulant and flocculant reagents, pH adjustment, followed by a regulation tank. The effluent thus treated can undergo an ultrafiltration membrane system that ensures the almost complete removal of oils and fats.

Primary Treatment: Degreasing + screening + physicochemical + UF

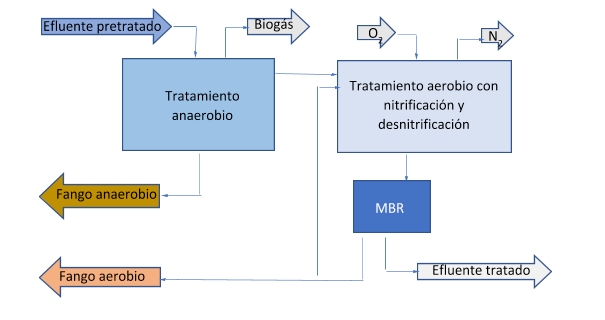

Biological Treatment:

Due to the high COD loads normally present in these effluents, and the temperature usually ranging between 25-30 ºC, an anaerobic biological treatment is necessary, which will reduce the COD by 70-80%, using a UASB process or more advanced processes like EGSB or PAQUES, capable of achieving higher yields with less space required. An important advantage of anaerobic technology, in addition to its practically zero energy consumption, is that the production of biological sludge is much lower than that of aerobic biological processes, and biogas is generated, which can be burned in a specific boiler after treatment, providing the factory with a significant amount of recovered energy that can be used for its processes.

Anaerobic treatment technology has relatively low nutrient consumption, so the nitrogen consumed for treatment will be low, and if the input is high (as is usually the case), a nitrification-denitrification process will be necessary in a subsequent aerobic biological treatment; this reduces both the nitrogen content and the residual COD content to the limits allowed in discharges.

Secondary Treatment: Anaerobic – Biological with nitrification and denitrification + MBR

Tertiary Treatment: MBR

The effluent thus treated can be partially reused in some processes within the emitting factory, but if an MBR system is also installed in the aerobic biological system, instead of a secondary clarifier or flotation unit, the quality obtained in the treated effluent will be much higher, and it can be used in more points of the factory, thus achieving minimal final discharge.

Effluent treatment performance

The typical performance achieved in a wastewater treatment plant for this type of industry is approximately as follows:

| PRODUCT | RAW EFFLUENT | AFTER PHYSICOCHEMICAL TREATMENT | AFTER BIOLOGICAL TREATMENT |

| BOD5 (mg/l) | 2000-6000 | 600-2500 (60%) | <30 |

| Suspended Solids (mg/l) | 1000-6000 | 100-300 (98%) | <30 |

| Oils and Fats (mg/l) | 200-2000 | 100 (90%) | <50 |

With an MBR system as tertiary treatment, values of < 10 ppm of SS can be obtained, and a similar proportion for the rest of the pollutants.

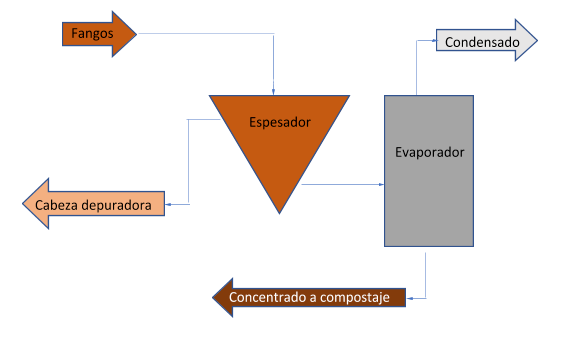

SLUDGE DRYING:

The sludge separated in the pretreatment and aerobic biological treatment is sent to a thickener to concentrate it from approximately 2-3% to 6-8%; the anaerobic sludge will be reserved for possible incidents, or it will be sold as a byproduct for other treatment plants.

The thickened sludge is usually treated with lime and flocculant and then subjected to dehydration with a filter press or centrifugal decanter in order to dispose of it in a landfill or for composting.

If a vacuum evaporation system is used, much higher concentrations can be achieved, and its destination will be more commonly for composting, as it will contain fewer pollutants.

One of the advantages offered by anaerobic treatment is the production of biogas that can be used to generate energy in a boiler, and from this energy, the energy consumption is reduced, making the evaporation process more viable, which is much cleaner and more efficient than traditional mechanical drying.

Sludge Drying with Evaporation

CONVENTIONAL TREATMENT AND ALTERNATIVE OPTIONS

Conventional treatment would be based on an aerobic biological process to remove dissolved organic matter, which accounts for approximately 70% of the total organic matter.

However, prior to the biological process, it would be convenient to screen the water using a rotary sieve with a passage size of 1-2 mm and remove the present fats.

Fats greatly hinder the biological process, so it is advisable to separate them beforehand. Fats reduce the rate of oxygen dissolution in water and form a layer on the surface of the biomass, thus reducing the transfer of dissolved oxygen to the biomass.

Fats are separated from the water by flotation through the addition of fine air bubbles, which help the fat particles reach the surface more quickly. Once separated from the water and concentrated, fats are managed externally (incineration).

Next, the water is biologically treated using a system that allows for nutrient removal. After secondary settling, the water can be discharged, while the separated sludge must be thickened, dehydrated, and managed externally.

This sludge must be stabilized through composting, anaerobic digestion, thermal drying, etc.

Another treatment option, more innovative than the aerobic biological process, is the transformation of organic matter in wastewater into biogas through an anaerobic system such as UASB (Upflow Anaerobic Sludge Blanket).

Anaerobic biological processes are more efficient and cost-effective when the influent has a high concentration of biodegradable organic compounds. Compared to the aerobic biological process, less energy is consumed, and biogas is produced, which can be used to generate electricity through cogeneration.

Furthermore, sludge production is considerably lower in anaerobic systems. In a UASB reactor, the influent is fed from the bottom.

It passes through a settled sludge blanket at the base of the reactor in an upward direction and enters the digestion zone. The treated effluent and generated biogas are removed from the top. These types of reactors are very compact, occupy little space, have low operating costs, and achieve very high removal percentages of BOD (over 95%).

Another alternative, more innovative and also yielding very good results at a laboratory and pilot scale, is electrocoagulation. Studies conducted so far demonstrate that very good removal results of organic matter can be achieved at much lower operating costs than conventional technologies.

SUMMARY

The dairy industry sector is one of the basic and most important for human nutrition. In terms of the environment, water consumption is high, and the treatment of generated effluents is complex, especially due to their high content of fats, COD, and nitrogen. However, good practices in factories and the use of technologies such as anaerobic biological treatment with biogas generation, ultrafiltration, and sludge drying with evaporation allow for optimization.

Bibliography and information obtained from the Internet

http://www.fao.org/dairy-production-products/socio-economics/social-and-gender-issues/es/

https://www.consalud.es/estetic/nutricion/la-leche-beneficiosa-o-perjudicial_51457_102.html