On November 12th, Condorchem Envitech attended the Water in the Meat Industry Conference held at the University of Vic, where a new R&D project developed by the university in collaboration with INnovacc, a cluster of companies in the meat sector, was presented. This project consists of a pilot plant for the treatment and valorization of the residual brine generated by the meat industry.

This project began in late 2011 with the aim of providing a solution to the problems of wastewater with high salinity arising from the production processes of the meat industry. Additionally, it aimed to optimize the treatment process of these brines in order to reduce the costs they impose on companies, whether through the reduction of waste to manage or by avoiding environmental penalties.

The meat industry is often concentrated in specific areas, so the treatment of brines can be key to both the productive efficiency of the sector and the economic competitiveness of these geographical areas. This innovation also represents an advantage for the wastewater treatment plants (WWTPs) in these areas, as they are often overwhelmed by this type of discharge.

This R&D project was developed by SART Medi Ambient (a knowledge and technology transfer center for companies in the environmental field at the University of Vic) at the request of INnovacc, in order to address the common problems of the 52 meat companies that comprise it. The companies associated with the cluster can use this pilot plant at their facilities to verify the effectiveness of this method and the advantages they would gain by applying this technology in their production process.

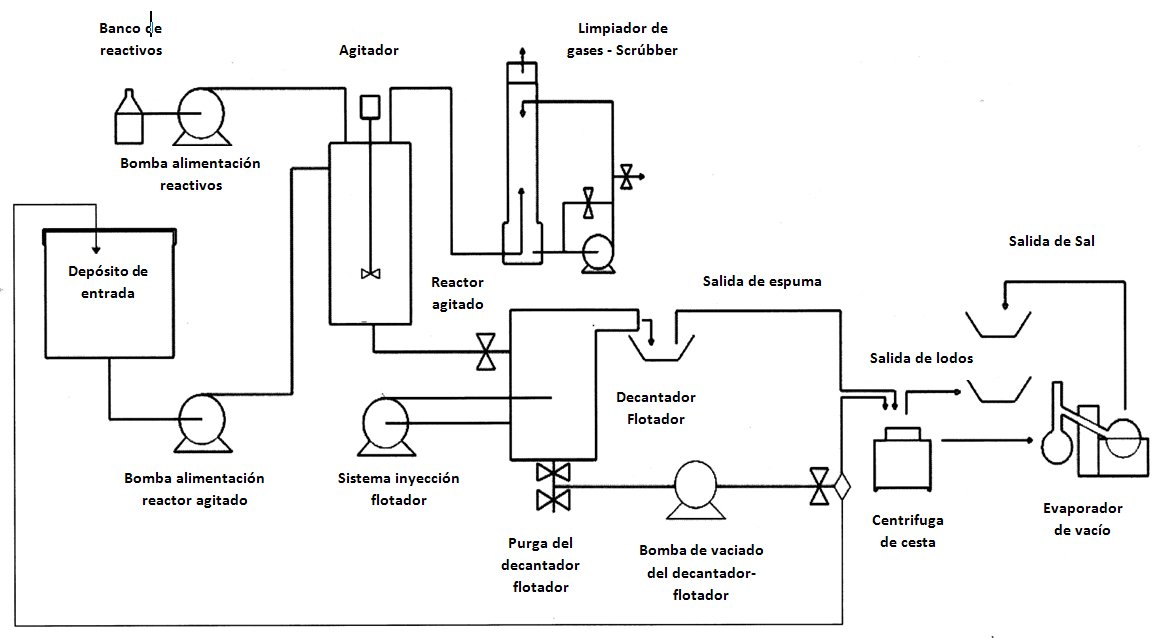

The pilot plant receives the brine and performs a triple separation, isolating the organic matter, salt, and water. The treatment process is as follows:

- The brine is neutralized with a flocculant.

- The neutralized brine undergoes a decantation process, after which we obtain wet sludge and a liquid fraction.

- The wet sludge is centrifuged, resulting in 30% to 40% solid sludge for management. The remaining distillate is sent along with the liquid fraction obtained in the previous decantation process.

- All the liquid fraction of the brine is sent to a partial evaporation process, which allows for the recovery of more than 75% of the salts. A concentrated liquid fraction is also obtained to be sent to a waste manager.

- This last phase could be carried out with a vacuum evaporator/crystallizer. It is a more expensive process than partial evaporation, but it improves the results, obtaining more than 95% clean water ready to be reused or discharged, and a large concentrate of salts, which can also be reused or sold. In many cases, the higher initial investment is justified by the significant savings achieved by not having to manage large amounts of sludge and concentrated liquid fractions.

The pilot plant allows for the evaluation of performance, the quality of the distillate and concentrate, cost, benefit, and the time required for the return on the initial investment. This pilot plant has great flexibility, allowing it to treat different types of saline effluents, making it potentially interesting for other types of companies.

The pilot plant’s itinerant nature across various companies in the sector has allowed for the verification of the objectives established at the beginning of the project:

- Both the environmental impact and the economic cost that companies have to face have decreased.

- General management costs have been reduced by around 40%.

- Annual savings are estimated to range from 30,000 to 50,000 euros.

- It allows for the valorization of the waste resulting from the treatment process of the plant.

- The distilled water obtained is suitable for reuse, and on the other hand, the extracted salts and proteins can be sold and used as fertilizer or pet food.

Here is the diagram of the solution proposed by SART Medi Ambient: