Project details

- Client: Freixenet

- Year: 2006

- Location: Sant Sadurní d’Anoia – Spain

- Sector: Supply

- Division: Industrial wastewater / Waste recovery

Project description

The Freixenet Group is a family business that has 18 wineries in 7 countries on 3 continents.

Other Condorchem Envitech projects for the Freixenet Group: UCSA (Unió de Cellers del Noya, SA).

Request 1: Treatment of 1250 m3/week of wastewater from the cava production process. The implementation of a purification process is requested to increase the efficiency of the previous process by 20% and respect the local landscape as far as possible.

Request 2: Concentration of effluent with ammonium sulfate from a cava bottle chemical grinding plant.

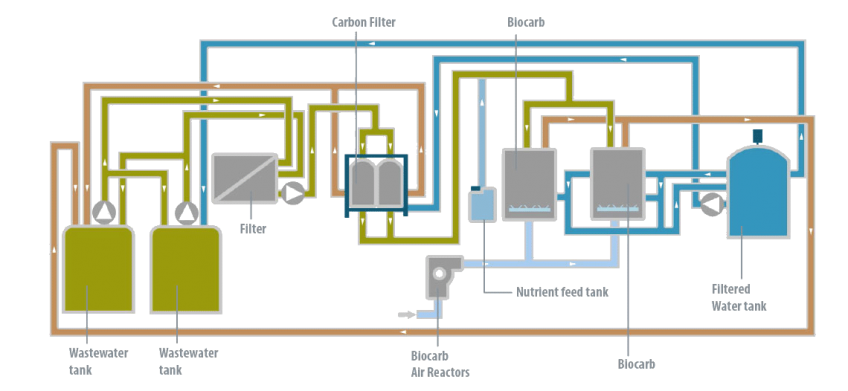

Solution 1: Complete biological treatment plant BIOCARB 2 x 25 MC.

Solution 1: ENVIDEST MVR FF 1500 vacuum evaporator made of a special anticorrosive material.

Results

Residual effluent discharge to conform at the collector (Biocarb Plant).

TRUE ZLD Recycling of distilled water to process and to obtain a concentrated solution of ammonium sulfate as a by-product to be sold to third parties.