Project details

- Client: Arcelor Mittal (Avilés and Lesaka factories)

- Year: 2006

- Location: Avilés, Spain / Lesaka, Spain

- Sector: Metalworking and electroplating

- Division: Industrial wastewater

Project description

Arcelor Mittal is the world’s leading steel and mining company, present in 60 countries, with a workforce of 210,000 employees. With industrial facilities in more than 19 countries, it has an annual production capacity of 114 million tons of liquid steel.

Avilés request: Treatment of 240 m3/week of emulsion from the process of washing strip steel before painting.

Lesaka request: Treatment of 150 m3/week of oily emulsion from strip steel rolling mills.

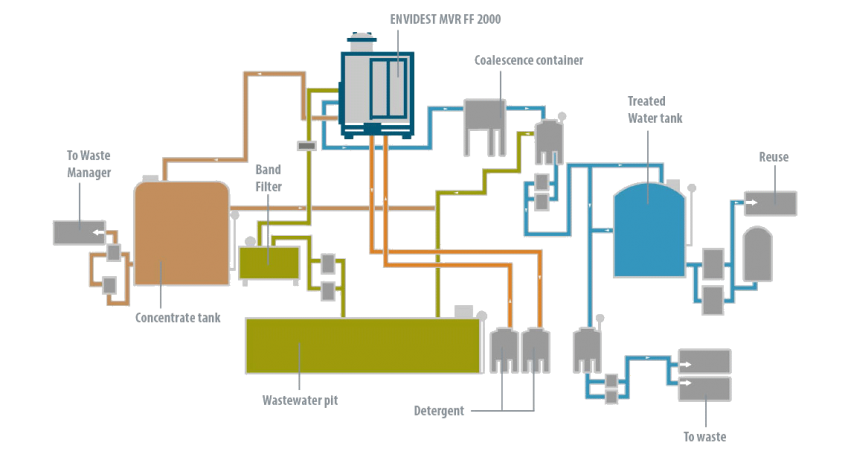

Avilés solution: Complete plant with ENVIDEST MVR FF 2000 evaporator + distillate refining with activated carbon + peripherals.

Lesaka solution: Complete plant with ENVIDEST MVR FF 1500 evaporator + distillate refining with activated carbon + peripherals.

Results

Discharge within legally established limits.