Sections

INTRODUCTION

Historical Overview

The history of beer dates back to ancient times. With the development of agriculture between 10,000 BC and 6,000 BC, products made from its fruits began to be discovered, leading to the belief that beer was likely discovered during that time.

The discovery of “bottom fermentation” around the 15th century and the introduction of hops made beer more appealing to consumers, making it commercially more attractive.

Hops prevailed over other herbs and spices because they improved preservation and consequently transportation and marketing, in addition to influencing the body and flavor of the beer.

In 1883, Carlsberg Brewery began the industrial production of “lager” beer using a yeast strain previously isolated in solid media. This event became a milestone of the industrial revolution, marking the transition from small-scale artisanal brewing to modern large-scale production.

This was soon followed by other companies, becoming a standard technique in Europe and North America in the following years, leading to exponential growth in beer production.

Today, the brewing industry occupies a central position in the global food industry, with production exceeding 1,500 million hectoliters per year, making beer the fifth most consumed beverage in the world.

Global Producers and Consumers

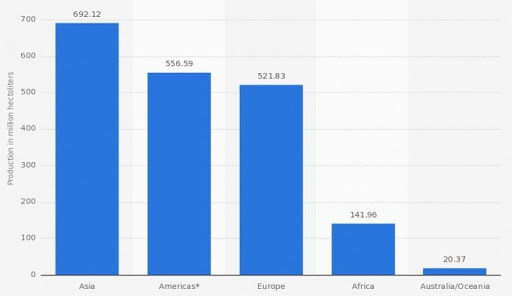

The following graph shows the largest beer producers in the world:

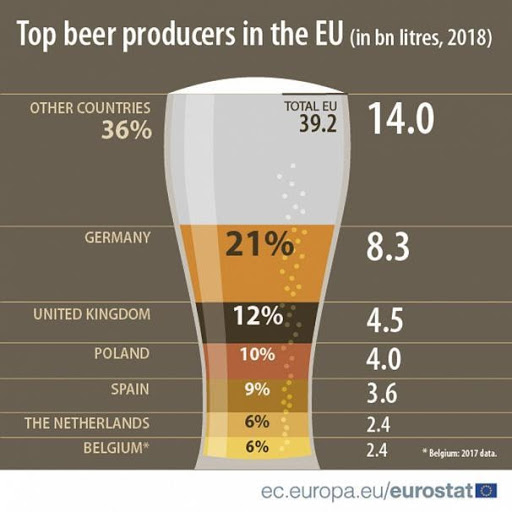

Europe is the continent where the most beer is consumed in the world. Eight of the top ten global consumers are EU countries. Europe produced 39 billion liters of this beverage in 2018. The production of beers with 0.5% alcohol and non-alcoholic beer also increased, reaching 1 billion liters.

Italy is the country that increased its production the most compared to 2017, by 21%, followed by Hungary (11%) and the Czech Republic. In contrast, the United Kingdom has reduced its production by 20%. Austria, Slovakia, and the Netherlands have also decreased their production, albeit to a lesser extent.

Germany continues to lead the beer market with 8.3 billion liters and 21% of the business. In other words, one in five beers produced in the EU is German. It is followed by the United Kingdom, with 12% of production, Poland (10%), and Spain with 9% and an increase of 20 million liters between 2017 and 2018.

The reputation of Germans as brewers is confirmed because, despite being the largest producers, they are not the largest exporters; the Netherlands leads with 1.9 billion liters, 300 million liters more than Germany.

According to Eurostat statistics, the main destination for European beer is the United States, with 1 billion liters (29%), followed by China (13%) and Russia (6%).

Europe imports little beer from outside the Union, mainly Mexican beer, at 250 million liters, which accounts for 52% of imports, followed by Serbia (57 million, 9%) and Belarus (5%).

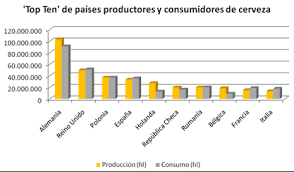

In this other graph, the largest European beer producers and consumers are presented:

Basic Beer Production Process

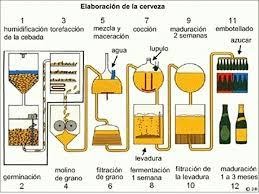

The beer production process is mainly divided into 3 stages:

- In the first stage, the starch contained in barley grain (or other cereals like rice, wheat, etc.) is converted into fermentable sugars, resulting in a sugary liquid called wort.

- In the second stage, the wort is fermented by yeasts to convert the sugars into ethanol and other minor compounds, resulting in beer.

- In the third stage, the obtained beer is clarified, filtered, and packaged.

WATER CONSUMPTION AND EFFLUENT POLLUTION

Water is the main component of beer, constituting approximately 95% by weight of the product. But besides being the primary raw material, it is an indispensable substance for the functioning of a large number of operations. The main uses of water in beer production are:

- Cleaning of equipment and facilities

- Incorporation into the product

- Cooling circuits and boilers

- Packaging

- Sanitary uses

Regarding the water incorporated into the product, it is important to note its significance, both from the perspective of product quality and its influence on the total consumption of the facility.

If the chemical composition of the supply water in the area where the facility is located is not suitable for direct use as raw material, a series of treatments to remove and/or add certain mineral constituents is necessary to adjust the appropriate concentration of ions, in order to avoid harmful effects on the quality of the worts and beers and on the operation of the processes and equipment.

This prior conditioning of the water, often unavoidable, can significantly increase consumption since the required composition adjustment cannot be made without a certain loss of water.

These losses occur in the form of concentrates or rejects if methods based on reverse osmosis or electrodialysis are used, or as water from the regeneration of ion exchange resins if this solution is chosen.

The volume of wastewater generated in breweries corresponds to the total water consumed minus the water incorporated into the final product, the water evaporated during production operations and auxiliary services, and the water absorbed in the solid matrix of the generated waste.

The total volume of wastewater discharged in production centers ranges from 2.5 to 7.2 hl/hl. This wide range of emissions is directly related to the level of water consumption and the efficiency of management that each factory applies to this resource.

By balancing the volume of water consumed with the volume of wastewater discharged, it is found that the water that does not leave the facility as residual effluent fluctuates between 1.4 and 1.9 hl/hl of packaged beer, which in relative terms translates to 16.2%-43.1%.

These percentages are distributed among the water incorporated into the product, the water retained in solid waste, and the water emitted to the atmosphere as vapor.

The total volume of wastewater produced mainly comes from the cleaning operations of equipment and facilities, and it is also the stream that usually contributes the most significant pollutant load, as cleaning solutions contain various chemical substances such as cleaning and disinfection agents, and come into direct contact with the surfaces of equipment, pipes, and tanks that have transported or contained wort, beer, or raw materials, significantly increasing the organic load and the amount of suspended solids among other parameters.

Other significant effluents originate from the packaging line. At the head of the packaging trains, the conditioning of barrels and reusable containers is carried out.

The residual stream generated in this area is important not so much for the volume produced, but for the pollutant load it contributes.

Its characteristics are similar to those of cleaning effluents from equipment and facilities, as they involve the use of more or less aggressive chemicals along with the removal of beer residues and solids that may be present in the containers.

Another significant point of wastewater generation in the packaging line is the pasteurization tunnel. This equipment has traditionally been a point of high water consumption and emission, although current designs of pasteurization tunnels have been adapted to avoid both water discharge and energy consumption.

The following table indicates the indicative pollutant loads produced in each activity of the production system for this product:

Average Parameters:

| Parameter | Unit | Concentration |

| Wastewater discharge | Hl/Hl beer | 3.5 – 8 |

| BOD of non-settled water | mg O2/l | 3300 |

| COD of non-settled water | mg O2/l | 1100 |

| Total nitrogen | mg/l | 30 – 100 |

| Total phosphorus | mg/l | 30 – 100 |

Pollutant Loads by Activities:

| Source | BOD (mg O2/l) | Kg/m3 beer |

| Water for malt milling | 4000-6000 | 0.67 |

| Wort filter tank | 9000-12000 | 0.58 |

| Washing filter tank | 7000-10000 | 0.23 |

| Trub | 194000 | 2.65 |

| Yeast from fermenters | 361200 | 12.4 |

| Yeast from storage tanks | 259300 | 5.45 |

| Beer filter rejects | 55000 | 1.0 |

| CIP cleaning solution | 2000-15000 | |

| Beer loss | 191000 | 1.91 |

| Overflow from bottle washers | 500 | 0.45 |

| Bottle washer solution | 200-10000 | |

| TOTAL | 25.34 |

EFFLUENT TREATMENT

The most notable characteristic of brewery wastewater is its high organic load and high biodegradability, which favors its purification possibilities through biological methods; in addition to the inevitable variability linked to the multiple management options and specific uses of water carried out in each production center, the conditions of the effluent drainage networks must also be considered, as the degree of segregation of the streams has a marked influence on the volume and pollutant load of the wastewater entering the treatment system.

The different treatment systems available to breweries and the way they are operated are also an important factor of variability, as can be inferred from the data in the previous table.

The treatment efficiencies can vary significantly for this reason and due to the different discharge limits imposed on different facilities based on the final discharge point and wastewater legislation.

Current trends in the treatment of wastewater from the brewing industry are directed towards a treatment system composed of:

Primary Treatment:

In this phase, suspended solids are removed with a coarse screening followed by a fine screeningprimary decantation is carried out, in which approximately 1/3 of the organic matter (that which is suspended as small solids or in colloidal form) is separated.

Secondary Treatment:

After homogenizing the discharges, an anaerobic biological treatment is carried out. This technology allows for a reduction of BOD by approximately 80%, with the advantage that practically no sludge is produced, which can also be valorized, and very few nutrients are required.

The anaerobic process must be carried out at around 25 – 30 ºC to be economically viable, so in many cases, it is necessary to heat the effluent; however, since there are discharges of hot water, such as from cooking or pasteurization, it is common to fall within this operational temperature range without additional energy input.

An important advantage of the system is the production of biogas, which can then be used as fuel to generate energy.

When discharging to an industrial polygon or another treatment plant, with this treatment and a slight final adjustment, the limits required by the authorities, which are around 1000 ppm of BOD, are usually met.

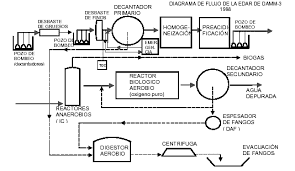

In the case of discharging into the public domain, a polishing treatment consisting of an aerobic biological treatment is necessary, which achieves levels of around 160 ppm of BOD and < 300 ppm of SS. The sludges from the primary and secondary decanters are concentrated in a thickener and sent to an aerobic digester. These sludges are finally dehydrated in a centrifuge or another mechanical or thermal drying system. The following diagram represents the basic treatment indicated:

An efficient alternative is to treat the more contaminated discharges with vacuum evaporation systems, in which Condorchem Envitech has proven experience.

In this case, the treatment line of the treatment plant can be considerably simplified; this technology is also applicable to the drying of sludges to reduce their volume and the cost of sending them to landfill. Evaporation technologies become viable by utilizing the energy released in the anaerobic treatment (biogas).

We can thus think of a mixed system between technologies that seeks the highest efficiency and the lowest energy consumption.

WASTE RECOVERY

Most of the production waste generated in breweries is organic in nature, which can be considered as by-products since they can be utilized by other industries (human food, animal feed, pharmaceuticals, etc.) or for agricultural use as organic fertilizer.

Given the potential commercial value of the solid waste generated in the production process and the high BOD5 they present, it is advisable to minimize the discharge of these along with the wastewater.

High quantities of waste similar to urban waste (glass, cardboard, plastics, metals, etc.) are also generated from the operations of raw material reception and packaging.

There are certain wastes, considered hazardous, generated during the maintenance of facilities (used oils, fluorescent tubes, solvents, hazardous packaging waste, etc.) that are common to those generated in any other activity, and their management must be appropriate. A classification of the generated waste can be made based on their different nature.

The following presents the quantities of waste, grouped into four categories. The classification as “waste” or “by-product” will depend on the final destination given to that production residue.

Organic Waste/By-products (kg/Hl of packaged beer)

- Spent grains and trub 16.99-23.09

- Yeast 1.4-3.61

- Malt dust 0-0.49

Urban-like Waste (kg/hl of packaged beer)

- Glass 0.11-1.64

- Plastic 0.02-0.1

- Cardboard 0.03-0.18

- Metal 0.01-0.124

- Wood 0.01-0.166

- Trash 0.09-0.55

- Others 0-0.04

Hazardous (kg/hl of packaged beer)

- Packaging 0.00021-0.005

- Fluorescents 0.002-0.012

- Solvents 0.00001-0.0003

- Others 0.0005-0.0113

Among the organic wastes, spent brewer’s grains (BSG) is the most abundant by-product generated by the beer brewing process, representing approximately 85% of the total by-products obtained. Spent grains refer to the residue of beer after its juice has been extracted.

After the mashing process, the insoluble part of the barley grain, the BSG, is in solution with the soluble wort (liquid).

The wort, which will be fermented into beer, is filtered and separated from the solid residue (BSG), which is a by-product that can be valorized.

Spent brewer’s grains typically consist of 15 – 26% protein and 70% fiber, which includes cellulose (between 15.5 and 25%), hemicellulose (28 to 35%), and lignin (approximately 28%).

It may also contain lipids (between 3.9 and 18%, of which 67% are triglycerides), ash (2.5 to 4.5%), vitamins, amino acids, and phenolic compounds.

Mineral components include calcium, phosphorus, and selenium.

It also contains biotin, choline, folic acid, niacin, pantothenic acid, riboflavin, thiamine, and vitamin B6. Among the amino acids, leucine, valine, alanine, serine, glycine, tyrosine, lysine, proline, threonine, arginine, cysteine, histidine, isoleucine, methionine, phenylalanine, tryptophan, glutamic acid, and aspartic acid are present.

Utilizing spent grains is an effective measure to strengthen sustainable production and low-emission practices, which are recommended as the focus of the “Climate Change Action Plan,” according to the Law on adaptation and mitigation to climate change (Law No. 3871/11).

It also contributes to the goals of target 12 on responsible production and consumption of the 2030 Agenda for Sustainable Development Goals (SDGs) set by the United Nations.

For all these reasons, spent brewer’s grains have a wide range of possible destinations, including:

- Human consumption.

- Energy production through direct combustion.

- Biogas production through anaerobic fermentation.

- Charcoal production.

- Use as an adsorbent material for chemical treatments.

- Cultivation of microorganisms.

- Obtaining fermentation bioproducts.

The high initial water content (75–80%) and the presence of considerable levels of polysaccharides, residual fermentable sugars, and proteins make fresh spent grains susceptible to microbial contamination, mainly by filamentous fungi. This microbiological deterioration can compromise the possibility

The average annual global production of BSG is estimated at 39 million tons, with 3.4 million tons produced in the European Union, of which 2 million are produced in Germany alone.

About 20 kg of wet BSG are produced for every 100 liters of beer brewed. Currently, most of the produced spent grain is used as low-value animal feed, with a market price of approximately €35/ton. The main components of BSG include fiber (30-50% w/w) and protein (19-30% w/w), which are basic nutritional components in the human diet and therefore make this material very attractive for improving the nutritional value of foods.

Additionally, several components that are constituents of BSG, such as arabinoxylans, hydrolyzed proteins, and phenolic compounds, have gained increasing attention for their potential health benefits.

Due to the significant amount produced annually, the current low market value, increased environmental awareness, and recognition that BSG can represent a nutritionally valuable co-product, efforts are increasingly focused on the valorization of this agro-industrial by-product.

The second by-product in terms of volume generated is yeast. Yeast is added in small amounts to fermentation tanks to transform sugars into ethanol and CO2.

During fermentation, a quantity of yeast approximately four times greater than the amount introduced is produced and is removed from the tanks once fermentation is complete.

Part of this removed yeast is reintroduced into the tanks to maximize its fermentative activity, but most must be managed as a recoverable by-product in other industries.

Yeast outputs also have the potential to be used in animal feed, in addition to serving as raw material in the food, cosmetic, and pharmaceutical industries.

However, the ease of acceptance by third parties as raw material largely depends on its moisture content, so greater dehydration leads to higher market acceptability.

The surplus yeast consists of a suspension of yeast in beer at various stages of fermentation, with a solid concentration close to 10% w/w.

Its volume can reach 1-3% of the volume of beer produced and is sold to the animal feed industry in most breweries.

However, its use is the subject of intense laboratory research to obtain value-added products.

For example, it can be used for the production of oligosaccharides, bacterial cellulose, bioethanol, co-digestion with washing effluents in high-load anaerobic reactors to increase methane production, and as fish feed.

The most efficient technology for dehydrating both spent grains and yeast is Vacuum Evaporation, in which Condorchem Envitech provides numerous proven solutions.

The wide variability of the values in the range of residual yeast production is due to the very different degrees of dryness it can have at the time of quantification and the number of times it is reintroduced into the fermentation tanks.

Malt dust is one of the main potential environmental aspects regarding atmospheric emissions.

Malt dust emission control systems facilitate the partial recovery of this dust, and depending on various factors, including collection conditions and the type of processes carried out, it can be reintroduced into the process or used by third parties as animal feed. Condorchem Envitech has cutting-edge technologies for gas treatment.

SUMMARY

Beer is one of the most consumed beverages in the world, being considered one of the best refreshers, while also recognized for its nutritional contribution to human nutrition.

In the beer manufacturing process, practically everything is utilized, as the effluents produced are usually treated in anaerobic digesters that produce methane gas, used as a powerful fuel for biogas boiler feeding and energy generation.

A large part of the waste obtained in the manufacturing processes is recyclable as raw material (yeasts) or considered as by-products with multiple applications (spent grain BSG).

In this regard, the treatment of vacuum evaporation is a technology applicable in these processes, as they are industries that can generate energy (anaerobic treatments), and the recoverable waste should have the lowest possible moisture to facilitate transport and reduce the possibility of decomposition.

Bibliographic and Internet References

https://upcommons.upc.edu/bitstream/handle/2117/115468/Los%20residuos%20de%20cerveza%20como%20fuente%20de%20antioxidantes%20naturales.pdf?sequence=1&isAllowed=y https://dialnet.unirioja.es/servlet/articulo?codigo=2675308

http://www.alimentosargentinos.gob.ar/HomeAlimentos/Nutricion/documentos/TendenciaBagazo.pdf

https://bibliotecavirtual.unl.edu.ar:8443/bitstream/handle/11185/905/Tesis.pdf

http://prtres.es/Data/images/Guía%20MTD%20en%20España%20Sector%20Cervecero-A2401D26BE1CD61C.pdf

https://es.euronews.com/2019/08/02/quienes-son-los-mayores-productores-de-cerveza-de-europa