Condorchem Envitech Offer

Condorchem Envitech supplies photo-oxidation equipment for the treatment of volatile organic compounds emissions. Some of the most common configurations of our photo-oxidation equipment are:

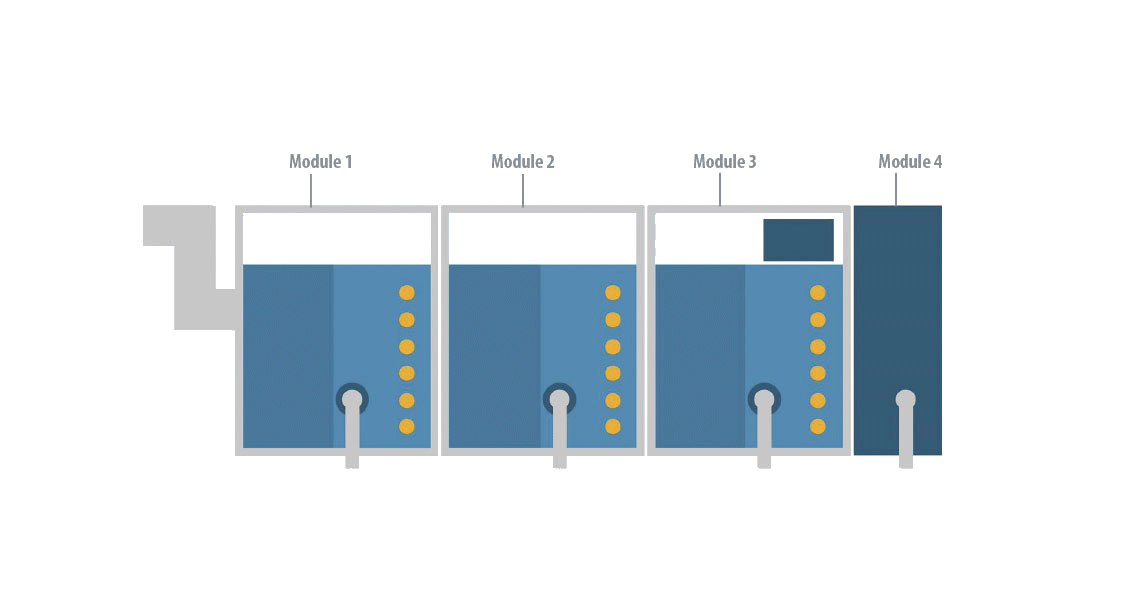

- Photo-oxidation module from 20kW to 200kW.

- Photo-oxidation module with a previous scrubber.

- Photo-oxidation module with ozone generator from 0.5 to 20kg / h.

The Condorchem photoxidation technologies present a number of important advantages over other traditional technologies for VOC reduction:

- Removes smell and pollution from industry emissions.

- Low operating costs.

- Instant response to variable loads.

- Energy efficient.

- No or little pressure drop, no static filters.

- No consumables.

- No waste products.

- No added chemicals or detergents.

- Replaces existing infrastructures, e.g. chimneys.

- Modular system for easy and flexible installation.

Technical characteristics

- Flow rates between 500 and 150,000 m3 / h.

- The concentration is directly proportional to the amount of energy (UVs lamps) to be used.

- The operating temperature of the equipment is up to 70 ºC.

- Simple and basic maintenance.

- VOC removal efficiency up to 99%.

Main components

- Chamber of UV lamps.

- Main fan.

- Ozone generator.

- Gas washer (in some cases).

- Electrostatic precipitator (to collect particles).

- Ozone catalyst.

- Isolation.

- Process valves.

- Purge System.

Advantages

- It treats a wide variety of VOCs.

- The reactions are purely gaseous phase without increasing the temperature.

- No chemicals are needed with photo-oxidation.

- VOCs treated with photo-oxidation are automatically converted from gas into aerosol particles.

- No waste is generated during the process.

- Only electricity is used to generate oxidants (O3 and OH).

- Low Operating Costs.

- Energy consumption can be adapted depending on the inlet concentration.

Applications

Regenerative thermal oxidation is applicable to all processes liable to produce VOC emissions, which are very numerous, and generally belonging to the following industrial sectors:

- Iron and steel industry

- Plastic industry

- Food industry

- Timber industry

- Paint, varnish and lacquer industry

- Livestock industry

- Pharmaceutical industry

- Cosmetics industry

Introduction to photo-oxidation

The Climatic© technology uses advanced atmospheric oxidation to remove pollution from industrial emissions. This is achieved by combining the natural self-cleaning properties of the atmosphere in a closed system.

It applies to all those industries that battle with pollution and VOC issues including solvents, odor substances, dust particles, aerosols, organic hydrocarbons, chlorine by-products, etc.

The system works on the basis of natural chemical reactions that occur in the gas phase. Thus, the CLIMATIC approach does not consume energy to force the air stream through static filters with a limited treatment capacity. The result is a reduced pressure drop and energy consumption and a treatment system that can be actively tuned to match the load.

Initially, ozone is mixed with the polluted exhaust. The mixture is irradiated with high intensity UV light which transforms ozone into OH radical molecules. These are extremely reactive towards most pollutants, transforming these into aerosol particles which may be filtered off using an electrostatic precipitator.

A final stage of the process eliminates ozone excess through a catalyst. The nature of the radicals allows for a broad capture and neutralization of many different types of pollutants and many noxious chemicals stemming from painting, plastic processing, and VOC emitted from waste oil treatment.

The working temperature is up to 70°C. It can be applied to a wide variety of flow rates, between 500 and 150,000 Nm3 / h, with VOC concentrations ranging from 0.1 to 15 g / Nm3.

Functioning/operation of photo-oxidation

Condorchem Envitech’s system uses Gas Phase Advanced Oxidation (GPAO) to remove pollution from industrial emissions. GPAO accelerates and harnesses the natural self-cleaning properties of the Earth’s atmosphere in a closed reactor system, and captures the emissions before they pollute the environment.

The system works on the basis of natural chemical reactions that occur in the gas phase. Thus, this solution does not consume energy to force the air stream through static filters with a limited treatment capacity. The result is a reduced pressure drop and energy consumption, and a treatment system that can be actively tuned to match the load.

Initially, ozone is mixed with the polluted exhaust. The mixture is irradiated with high intensity UV light which transforms ozone into OH radical molecules. These are extremely reactive towards most pollutants, transforming these into aerosol particles which may be filtered off using an electrostatic precipitator. As a final treatment stage, ozone is removed by a catalyst.