Electrical Vacuum Evaporator by Heat Pump

The ENVIDEST LT VS series vacuum evaporator is designed to treat aqueous-based streams with a low contaminant load. The equipment operates with electrical energy and its heating and condensation system is based on a heat pump (HP) unit.

This equipment stands out for its superior energy efficiency within the range of single-effect heat pump evaporators. Thanks to its submersible coil-type heat exchanger, it has a larger exchange surface and requires less installation space.

The operation of the equipment is fully automatic - 24 hours a day.

Our evaporators ENVIDEST LT VS

Main features

- Technology: Heat Pump (Freon R-513A)

- Single/Multi-Effect: Single-Effect

- Vacuum: ≈ 60 mbar

- Evaporation Temperature: ≈ 35 °C

- Evaporation Vessel: Vertical

- Droplet Separator: Raschig rings

- Heat Exchanger for Heating: Submersible Coil

- Refrigeration Circuit: Single heat pump unit, or primary and secondary heat pump unit (depending on the model)

- Vacuum System: Venturi Ejector or liquid ring pump (depending on the model)

- Control Unit*: PLC Siemens with HMI touch screen

- Protection: IP54

- Electricity Supply**: 400 V III + PE 50 Hz

- Standard Manufacturing Material: 1.4401/1.4404 (AISI 316/AISI 316L)

- Special Anti-corrosion Manufacturing Material***: 1.4410 (Superduplex 2507)

* Different PLC manufacturer available on request

** Different voltage supply available on request

*** Consult other available material options

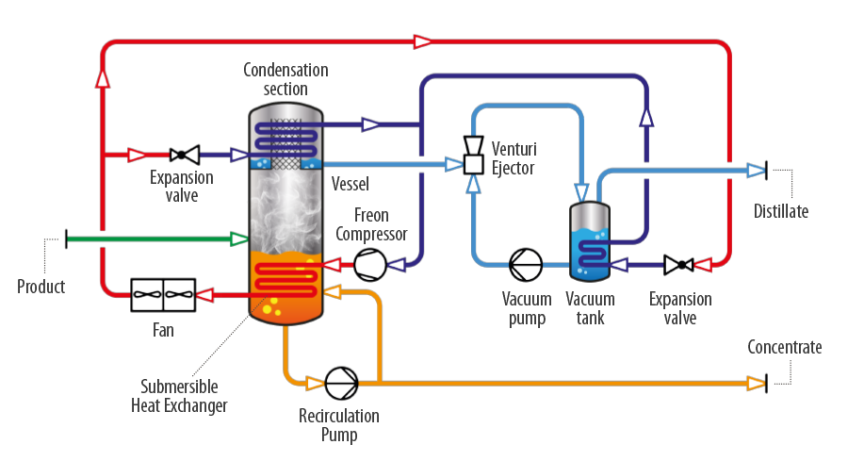

Diagram

Technical specs

| Parameter | Unit | 250 | 500 | 750 | 1000 | 1500 | 2000 | 2500 | 3000 |

|---|---|---|---|---|---|---|---|---|---|

| Capacity* | L/day | 250 | 500 | 750 | 1000 | 1500 | 2000 | 2500 | 3000 |

| Electricity Consumption** | kWh/m³ | 170 | 170 | 170 | 170 | 170 | 170 | 170 | 170 |

| Length | mm | 2050 | 2100 | 2200 | 2200 | 2800 | 2900 | 3000 | 3300 |

| Width | mm | 830 | 870 | 1000 | 1000 | 1300 | 1250 | 1350 | 1350 |

| Height | mm | 1900 | 2250 | 2200 | 2400 | 2400 | 2420 | 2700 | 2750 |

| Parameter | Unit | 4000 | 5500 | 7000 | 9000 | 10000 | 12000 | 15000 | 18000 |

|---|---|---|---|---|---|---|---|---|---|

| Capacity* | L/day | 4000 | 5500 | 7000 | 9000 | 10000 | 12000 | 15000 | 18000 |

| Electric Consumption** | kWh/m³ | 170 | 170 | 170 | 170 | 170 | 170 | 170 | 170 |

| Length | mm | 3500 | 3600 | 4000 | 4500 | 4500 | 4500 | 5600 | 5600 |

| Width | mm | 1350 | 1500 | 1500 | 2000 | 2000 | 2000 | 2250 | 2400 |

| Height | mm | 2840 | 3020 | 3250 | 3250 | 3310 | 3300 | 3900 | 4155 |

* Data refer to clean water when working continuously in standard conditions (T = 20 °C, P = 1013 mbar).

** Electricity consumption expressed in kWh per m³ of distillate produced.