The DESALT VR series vacuum crystallizer is designed for treating encrusting wastewater, as well as for achieving a high concentration of the product.

The equipment can be manufactured to operate using saturated steam or hot water to heat the product that needs to be concentrated. The condensation of the vapour produced from the wastewater is carried out by suppling cooling water.

Standard manufacturing in 1.4401/1.4404 (AISI 316/AISI 316L) stainless steel. According to the wastewater to be treated, the parts of the equipment in contact with the fluid can be made of special corrosion-resistant alloys.

Fully automatic operation 24 hours a day.

Our evaporators DESALT VR

Main features

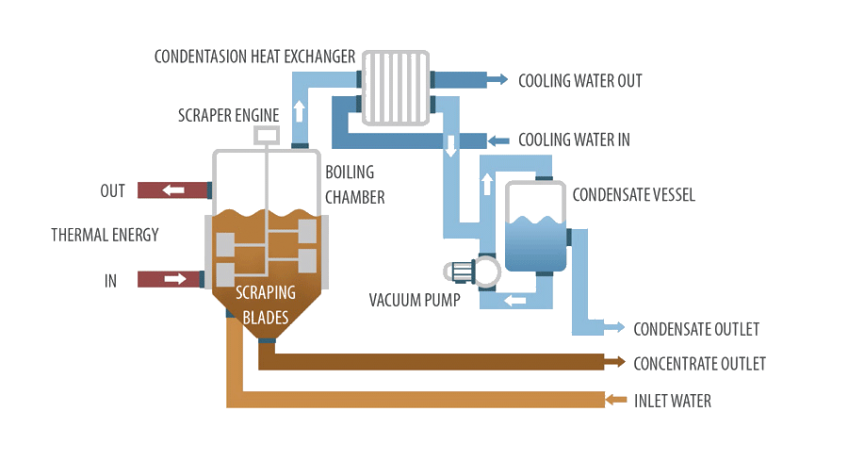

- Vessel: A detachable evaporation vessel with a conical bottom, made of stainless steel. It is equipped with an inspection glass, and it includes scraper blades placed inside the vessel for the continuous cleaning of exchange surface and homogenization of the product during concentration phase. It includes thermal insulation to prevent contact and improve energy efficiency.

- Main heat exchanger: The evaporation vessel incorporates an external, high-performance jacket heat exchanger to provide thermal energy for heating the product to be concentrated. It requires a saturated steam supply at 3 barg or, alternatively, hot water at 90 °C.

- Condenser: A stainless-steel plate heat exchanger to allow cooling of the vapour produced and, consequently, its condensation. It requires cooling water supply at 27 °C.

- Distillate tank: The distillate is stored in a stainless-steel tank and is discharged by a centrifugal pump controlled by level switches.

- Vacuum generation system consists of a liquid ring vacuum pump and a stainless-steel vacuum tank that contains chilled water to cool the vacuum circuit. The vacuum tank is equipped with a coil-type heat exchanger that requires a cooling water supply at 15 °C.

- Concentrate discharge: Automatic by means of a pneumatic pump (standard unit), single screw pump or by gravity. The duration of the concentration cycle is programmed with a timer.

- Instrumentation: Digital and analogue control instruments for the automatic monitoring of the system.

- Electrical command and control panel with emergency stop. IP54 protection. The power supply of the panel is 400 V, 50 Hz. Siemens PLC with touch screen for visualization and control of operating data.

- Supporting structure: Unit mounted on a stainless-steel skid.

Optional features

- Chiller to produce cooling water necessary for cooling the vacuum circuit.

- Teleservice Control System for remote assistance.

- Condensation by air condenser on request.

- Manufacturing with special material on request.

- Other voltage supply on request.

- Other PLC manufacturer on request.

Diagram

Technical specs

| Parameter | Units | 5000 | 6000 | 10000 | 20000 |

|---|---|---|---|---|---|

| Capacity | L/day | 5.000 | 6.000 | 10.000 | 20.000 |

| Electrical consumption | kWh | 4,6 | 4,6 | 4,6 | 4,6 |

| Evaporation thermal energy | kWht | 160 | 190 | 315 | 630 |

| Condensation thermal energy | kWht | 160 | 190 | 315 | 630 |

| Dimensions (L x W x H) | mm | 3300 x 2000 x 3945 | 4000 x 2000 x 4250 | 4100 x 2000 x 5000 | 4100 x 2000 x 5510 |