Project details

- Client: Standard Profil

- Year: 2006

- Location: La Rioja (Spain)

- Sector: Automotive / Aeronautics

- Division: Industrial wastewater

Project description

Standard Profil vulcanizes natural rubber profiles by dipping in a molten salt mixture based on lithium and potassium nitrates. After dipping, the profiles are rinsed by water in a counter current cascade, the first rinsing steep contains a high content of nitrates, which is impossible to treat by municipal sewage.

- Request: Standard Profil needed a solution to find a way to reuse the wastewaters and avoid discharging due to its high content of nitrates.

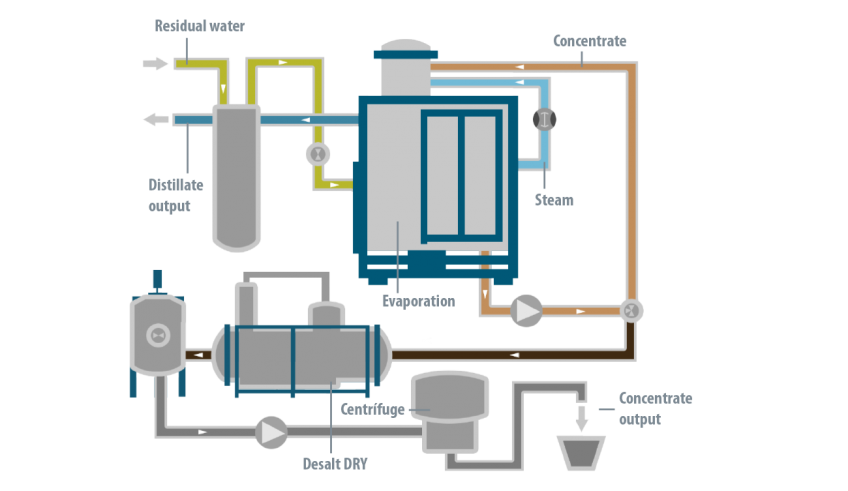

- Solution: ENVIDEST MVR FF 1000 + Vacuum dryer + Centrifuge

Results

The final salts have less than 3% of moisture. The recovered salts are melting in an electrical heated vessel to remove the rest of water moisture and reused again in the molten salt oven. By doing this, the client saves near 50 MT per year of commercial salts (-500k €/y) and about 4.000 m3/y of demi water.