Sections

- Waste in fish salting and seafood boiling

- Recycling and reuse of waste and effluents

- Processes used for waste recovery

Waste in fish salting and seafood boiling

The fish salting and seafood boiling industries produce wastewater with a high pollutant load that must be properly managed to avoid a negative environmental impact.

Depending on their origin and composition, these wastes are classified as:

Waste from fish salting

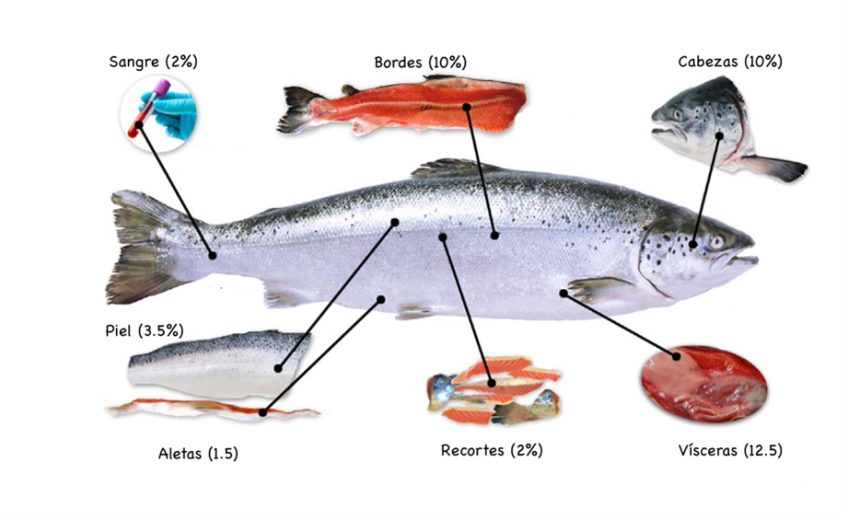

- Solid waste. They mainly come from the cutting and gutting stages and consist of remains of the processed fish, including parts such as heads, bones, tails, and viscera. These wastes are reused as raw materials for fishmeal production, significantly reducing their disposal in landfills.

- Liquid waste. They come from exhausted brines and are mainly composed of organic matter with a high content of proteins, salts, fats, and other suspended solids. Some examples of liquid waste are: blood water, washing waters from the cutting, gutting, and filleting stages, pulp pressing (in frozen products), and waters from cleaning operations.

The flow rates of residual effluent tend to be high, as these are production processes that require a large amount of water.

Waste from seafood boiling

- Shells and carapaces. They come from shrimp, prawns, mussels, crabs, etc.

- Cooking waters. They contain mineral salts, soluble proteins, peptides, and aromatic compounds.

- Organic waste in general composed of soft parts of these animals that are not initially marketable.

In both cases, the presence of gases and odors produced by volatile organic compounds generated during drying and other phases of the production process is common.

The discharge and disposal of these wastes without proper treatment can cause:

- Contamination of surface and groundwater.

- Emission of unpleasant odors.

- Proliferation of pathogens.

- Increase of pollutant load in landfills.

These wastes contaminate water and soil, as well as attract insects and generate unpleasant odors. Environmental regulations require the management of these wastes according to the following hierarchy:

- Prevention

- Reuse

- Recycling

- Valorization

- Disposal

In this context, valorization is presented as a priority alternative due to its environmental, economic, and social benefits.

Recycling and reuse of waste generated in fish salting and seafood boiling

To comply with the regulations mentioned above, there are various processes that allow the reuse of some of the components present in these wastes.

Water reuse

Less contaminated wastewater can be reused as washing water in the industrial process.

Meanwhile, water from autoclave cooling in canned food production can be used for cleaning equipment and the production plant.

Recovery of waste as by-products

Some of the most notable applications are:

- Use of seafood and fish waste in the preparation of pâté and/or animal feed, such as fishmeal production.

- Recovery of solids and fats from effluents through centrifugation, concentration, and subsequent dehydration for animal feed formulations.

- Use of shellfish shells for the development of products such as mineral flours.

Energy valorization

During the anaerobic digestion of organic waste rich in proteins and lipids, biogas is generated.

Technologies such as pyrolysis and gasification are used to transform biomass into energy.

From the drier fractions, such as shells or dehydrated remains, recovered solid consumables are obtained.

Nutritional and food valorization

- Fish and seafood meals obtained by drying and grinding waste. These meals can be used in aquaculture and animal feed.

- Protein extracts for dietary supplements or functional ingredients.

- Mineral salts obtained from the recovery of sodium, calcium, and magnesium from cooking waters.

- Waters from seafood boilers contain many flavors and nutrients, which can be used to make broths, soups, and bases for prepared dishes.

Valorization for pharmaceutical and cosmetic industry

- Chitin and chitosan derived from crustacean exoskeletons, with applications in cosmetics, medicine, and agriculture.

- Collagen and gelatin obtained from fish skins and bones, which can be used in cosmetic and pharmaceutical products.

Agricultural valorization

- Composting: production of organic fertilizers from biodegradable waste.

- Biostimulants: extracts that facilitate plant growth.

Processes used for waste recovery

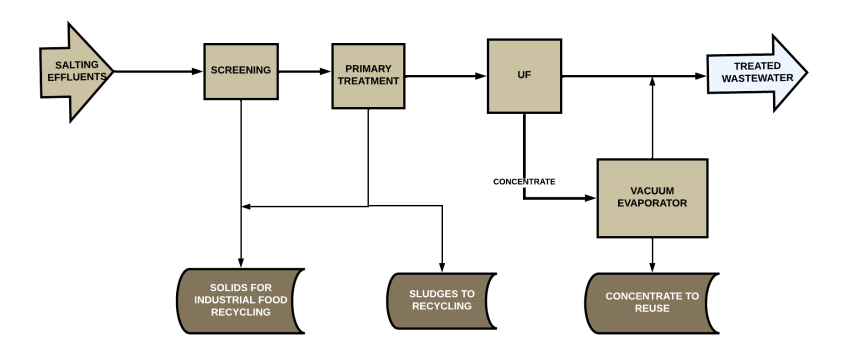

The most commonly used processes for the recovery of water and waste are:

- Filter screens.

- Clarification systems such as flotation units.

- Anaerobic digesters for energy production.

- Membrane filtration.

- Vacuum evaporation.

An innovative process consists of extracting and concentrating proteins and omega-3 rich fats for commercialization. This is achieved with the combined action of ultrafiltration membranes and vacuum evaporation equipment. Finally, drying equipment produces protein meal and oleic fatty acids, which are high-value products in the food market.

The remaining water, which usually contains high amounts of salt, can be treated with evapo-crystallization equipment, allowing the production of a clean effluent that can be discharged or reused. The calcium residue obtained after this process can be used for road de-icing as well as other industrial uses.

Filtration and concentration technologies allow going one step further in waste valorization, turning them into high commercial value products and facilitating the achievement of zero discharge.

Despite these advances, future challenges include:

- Expanding the provision of adequate infrastructure for the treatment of waste from fish salting and seafood boiling industries, optimizing separation and transformation costs.

- Meeting the need for certifications for products intended for food or cosmetic use.