Sections

- Biogas sources and types

- Origin of siloxanes

- Effect of siloxanes

- Siloxanes treatment

- CLEAN-BGAS® MP DRY solution

BIOGAS SOURCES AND TYPES

The energy sector is one of the most important and most developed today. Since the 20th century, the world has come to understand that it must renew and expand its energy sources to meet the growing needs of society, while taking care of the environment.

Biogas from landfill, methanation plants and wastewater treatment plants (WWTP) is a valuable material for energy production, biofuels and the production of chemicals, such as hydrogen and methanol. Being a renewable energy source, it is inexhaustible, clean and its use can be planned. It leads to less environmental pollution and is a viable alternative to the notable depletion of fossil fuels, such as natural gas and oil, where price increases have already been seen.

The energy sector is one of the most important and most current development. The world has understood, from the twentieth century which must renew and expand their sources of energy to meet the growing needs of society tending to turn the environment.

The biogas from landfills, methanation plant and wastewater treatment plant (WWTP) is a valuable material for the production of energy, biofuels and producing chemicals such as hydrogen and methanol.

As a source of renewable energy is inexhaustible, clean and can be used free of planned. Its use generates less pollution and are a viable alternative to the already sensitive depletion of fossil fuels such as natural gas and oil, and increased where it remains in their prices.

From a technical point of view, BIOGAS is a multicomponent mixture of gases, both in its basic composition (e.g. CH4, CO2, H2, O2, N2 and water vapor) and in its harmful components (e.g. NH3, siloxanes, halogenated hydrocarbons, BTEX, VOCs and H2S). Its composition is intimately related to the type of matter subjected to the anaerobic digestion process and, to a certain extent, the technology used for its production.

Thus, in general, there are 2 types of biogas:

- Uncontrolled systems. E.g. From landfill or marshland.

- Controlled systems. E.g. Municipal wastewater treatment plants (WWTP) and anaerobic digestion plants (high organic load).

In general, the latter are noted for their high concentration of H2S, its main contaminant, and, in the case of WWTP, siloxanes; while the former are noted for siloxanes and high molecular weight hydrocarbons.

Siloxanes come from the silicones present in materials such as shampoo, soaps, surfactants, oils and pharmaceutical products which are subject to anaerobic digestion processes.

From the process point of view, it can be stated that biogas is the gas from the anaerobic digestion of the organic fraction of different types of materials, and is noted for its high concentration of methane (CH4). This is what enables its use as a biofuel, where it is present at concentrations of 40-80% v/v of the gas generated in that process.

Every biogas use/recovery plant consists of 3 fundamental stages: biogas production (AD system), collection, cleaning and recovery system (electricity, steam, biofuels or as a raw material in the manufacture of other products).

All these stages are consecutive, that is, they operate linearly, each with a specific function. Cleaning/conditioning the biogas and its technologies plays a fundamental role, as it guarantees: 1 2 3

Optimum operation of the equipment and machines (e.g. engines, turbines, boilers and fuel cells) involved in its use as a fuel.

Prolonged useful life of the machines used for transport, extraction and compression (e.g. blowers and compressors).

Improvement in the exhaust gas emissions from the machines involved in energy production, as it removes much of the components causing this problem before they enter the process.

Reduction of machine maintenance costs (repairs and oil changes) involved in this type of plant.

ORIGIN OF SILOXANES

Among the components with the greatest impact on the energy use of the biogas generated in sewage treatment plants and landfill are siloxanes. These wear down the internal parts of the machines used, damaging them and reducing their useful life, as well as increasing operation costs due to repeated oil changes and internal parts replacement.

Siloxanes are a family of organic compounds formed by linear or cyclic chains of silicon, oxygen and methyl groups. They are manufactured in a range of types, including high and low viscosity fluids, gums, elastomers and resins. They are found in significant quantities in a wide and varied range of household products, such as detergents, shampoos, deodorants, toothpastes and cosmetics.

Most of them quickly evaporate into the atmosphere, and over time they break down into carbon dioxide, silica and water. However, some end up in wastewater and in municipal solid waste, and inevitably accumulate in landfills and treatment plants, where they are considered one of the most difficult pollutants to control.

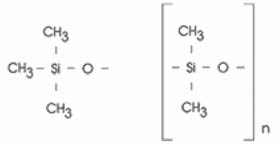

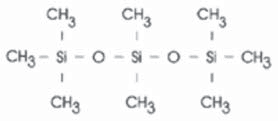

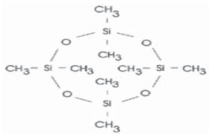

These are organic compounds formed from silicones, oxygen and methyl groups, with the structural unit -(CH3)2SiO, and molecular weight typically in the range of 150-600. Their solubility in water decreases with increasing molecular weight and they may or may not be be volatile. Figure 1 shows the structural unit of different types of siloxanes.

Figure 1.1 – Siloxanes nomenclature M and Dn groups

Figure 1.2 – Linear structure of octamethyltrisilioxane (MDM)

Figure 1.3 – Cyclical structure of octamethylcyclotetrasilioxane (D4)

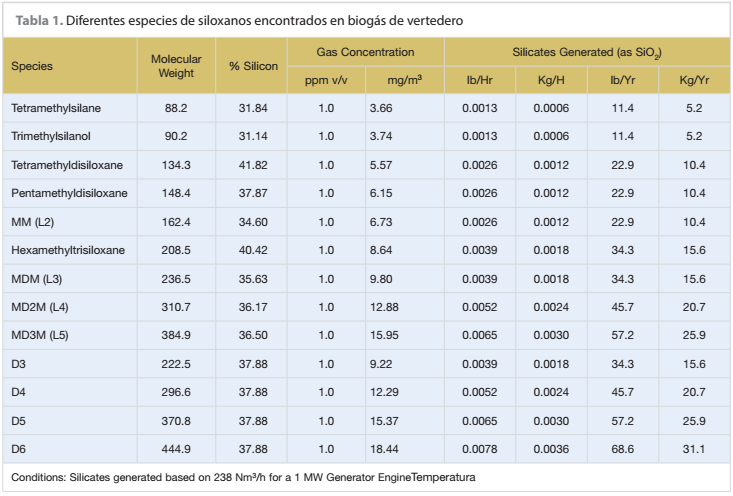

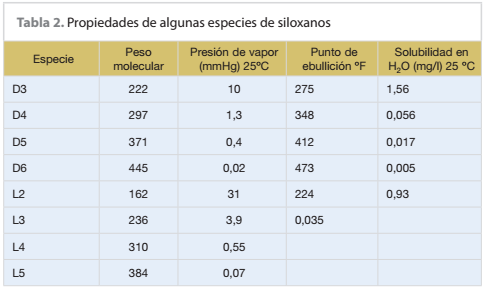

Tables 1 and 2 show some different types and basic properties of siloxanes found in biogas from landfill and WWTP.

EFFECT OF SILOXANES

Unlike sulphides, silicones do not react with water to form acids. However, during combustion, the siloxane molecules are broken down and release oxygen and silicon.

The latter combines with other elements forming silicates, silica and other crystalline compounds which are deposited in the combustion chamber (mainly in the upper part of the jacket), in cylinder heads and on the faces of valves. These deposits abrade and wear down different internal parts of the engines.

Figure 2 shows deposits caused by siloxanes in different types of machines.

Figure 2 – Motors

Figure 2 – Boilers

Figure 2 – Turbines

Permissible silicone contents for proper functioning of the production engines should in general be < 5 mg/Nm3, although each machine manufacturer sets its own limits. A higher content may cause silica deposition problems and burn out exhaust valves. As biogas turbines operate at such high rotation speeds of over 10,000 rpm, they require both very accurate static and dynamic balancing of their moving parts. This silica deposition can cause serious decompensation in them, leading to serious damage.

SILOXANES TREATMENT

Current systems to remove these compounds use techniques that generally have one or two stages involved. Among these are subcooling, adsorption on activated carbon/silica gel, graphite filters, certain types of resins and washing with certain reagents (e.g. methanol, sulfuric acid and hydrocarbon mixtures).

However, the most common techniques applied are shown below:

Cooling (Figure 3)

- to 4°C.

- Subcooling (to -25°C)

Adsorption

- Activated carbon

- Thermal regeneration

- Silica gel

Washing with certain reagents

Combination of techniques

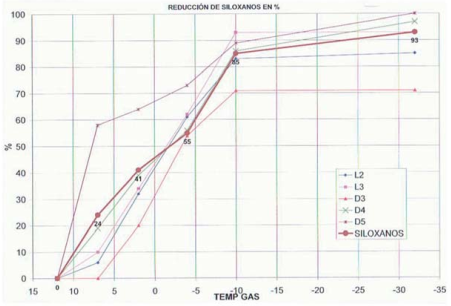

Figure 3 shows siloxane removal behavior with temperature.

Figure 3. Effect of temperature on the reduction of siloxanes

CLEAN-BGAS® MP DRY

CLEAN-BGAS® MP DRY is a multipurpose cleaning and conditioning technology based on combining operations, such as cooling, condensing, washing, drying and adsorption in activated carbon, which minimizes both energy and active carbon consumption.

The technology has two basic stages: one for the gross elimination of contaminants, including type D siloxanes, hydrocarbons, and biogas conditioning for input into active carbon filters via a thermal stage and another for refining (removal of siloxanes type L and D) by adsorption on activated carbon. An important part of this technology is the recovery wash that guarantees the conditioning of the biogas in all senses of the word.

Another advantage of this technology is that it removes both heavy hydrocarbons and those containing chlorine or fluorine, which, in turn, affect the proper functioning of the engine, as well as compliance with the power generation system emissions regulations.

This CLEAN-BGAS® MP DRY technology is the result of R&D work from Energy & Waste inside Condorchem Group, which has been working on cleaning and conditioning different types of gases, particularly biogas, for over 15 years (Figures 4 to 6).

Figure 4. Condensate before and after CLEAN-BGAS® MP DRY technology. Removal of hydrocarbons

Figure 5. CLEAN-BGAS® MP DRY Arico landfill site, Tenerife

Figure 6. CLEAN-BGAS® MP DRY. Mataró WWTP Barcelona

References.

[1].R.Huppmann, H.W. Lohoff, H.F. Schroder, Fresenius J. (1996). Cyclic siloxanes in the biological waste water treatment process- Determination, quantification and possibilities of elimination, Anal.Chem. 354 (66-71).

[2] Determination of Low Molecular Weight Silicones in Plasma and Blood of Women after Exposure to Silicone Breast Implants by GC-MS, Anal Chem., 2001, 73, 606-61 1.

[3] J. Reina. et al (Nov. 2002). Plant for biogas treatment for its use as biofuel. 9° Congreso Mediterráneo de Ingeniería Química. Barcelona- España.

[4] J. Reina. Humedad y siloxanos en el biogás generado en vertederos y depuradoras. Info enviro. Octubre 2006.

[5] J. Reina. Biolimp-Siloxa. Planta multipropósito para la limpieza del biogás. Infoenviro. Julio/agosto 2008.

[6] Estrella Jara. (Abril. 1999). La lubricación de motores a biogás.. Mobil Oil S.A. Infopower.

[7] M. Constant, H. Naveau, G.-L. Ferrero and E.-J. Nyns. Biogas end-use in the European community. Commission of the European communities. Elsevier applied science.

[8] Estibaliz. A, José. I. Ciria. (2004). Siloxanos en motores de gas. Boletín mensual sobre lubricación y mantenimiento.

[9] Jeffrey L. Pierce, PE. Vice President SCS Energy Long Beach, California. SILOXANE QUANTIFICATION, REMOVAL AND IMPACT ON LANDFILL GAS UTILIZATION FACILITIES. 8TH ANNUAL MOP CONFERENCE AND PROJECT EXPO. January 10-11, 2005. Baltimore, Maryland

[10] Dr. Robert Eden. SHOULD WE BE CONCERNED ABOUT LANDFILL GAS. http://www.organic.com.

[11] Dr. Joaquín Reina. Técnicas de Tratamiento del Biogás. http://www.ewtech-ing.com

[12] Biogás, parámetros comunes. Especialidad Siloxanos. Ingeniería analítica. S.l. Cromatografía y espectrometría.