The biological treatment of wastewater is carried out through a series of important treatment processes that share the common use of microorganisms (notably bacteria) to eliminate soluble components in water. These processes take advantage of the microorganisms’ ability to assimilate organic matter and nutrients (nitrogen and phosphorus) dissolved in wastewater for their own growth. When they reproduce, they aggregate and form macroscopic flocs with sufficient critical mass to settle in a reasonable time.

The traditional application consists of the removal of biodegradable organic matter, both soluble and colloidal, as well as the removal of compounds containing nitrogen and phosphorus. It is one of the most common treatments, not only for urban wastewater but also for a significant portion of industrial waters, due to its simplicity and low operational cost.

In most cases, organic matter serves as the energy and carbon source that microorganisms need for growth. Additionally, the presence of nutrients containing essential elements for growth, especially nitrogen and phosphorus, is also necessary, and finally, in the case of aerobic systems, the presence of dissolved oxygen in the water. Oxygen is not essential, as microorganisms can also degrade organic matter under anaerobic conditions. This aspect will be key when choosing the most suitable biological process.

In cellular metabolism, the final electron acceptor plays a fundamental role in the oxidation processes of organic matter. This aspect also has a significant impact on the possibilities of application for wastewater treatment. Depending on what the final electron acceptor is, three cases can be distinguished:

- Aerobic systems: oxygen is the preferred final electron acceptor for any cell. If oxygen is present in the medium, it will be the final electron acceptor, leading to high energy yields and significant sludge generation due to the high growth of bacteria under aerobic conditions.

- Anaerobic systems: in this case, the final electron acceptor is the organic matter itself, which acts as a carbon source. As a result of this metabolism, most of the carbon is directed towards the formation of growth by-products (biogas, which is CO2 and methane), while the fraction of carbon used for cellular synthesis is low. For treatment purposes, this fact presents a double advantage: little sludge is produced while biogas is generated, which can be valorized. It is usually used to produce electricity, which is self-consumed in the facility itself.

- Anoxic systems: These are systems in which the final electron acceptor is neither oxygen nor organic matter. Under anoxic conditions, the final electron acceptors are usually nitrates, sulfates, hydrogen, etc. When the final electron acceptor is nitrate, as a result of the metabolic process, the nitrogen in the nitrate molecule is transformed into nitrogen gas. Thus, this metabolism allows for the biological removal of nitrogen from wastewater (denitrification).

Advantages of each system according to criteria

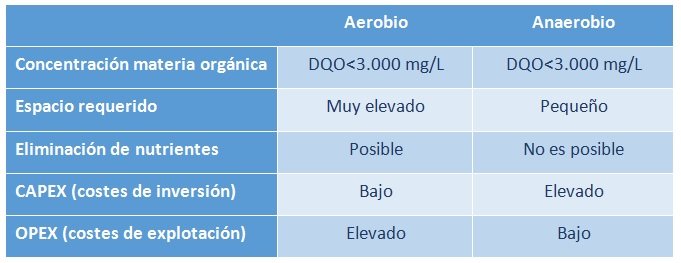

Considering all these aspects, there is a wide variety of ways to operate, depending on the characteristics of the water and the organic load to be treated. The criteria that help to select whether an aerobic process is more convenient or whether an anaerobic process will be more beneficial include the concentration of organic matter to be removed, whether nitrogen removal is necessary, the availability of physical space, and the relationship between OPEX and CAPEX of the project. The following table shows how, based on these criteria, which type of process (aerobic or anaerobic) is more convenient:

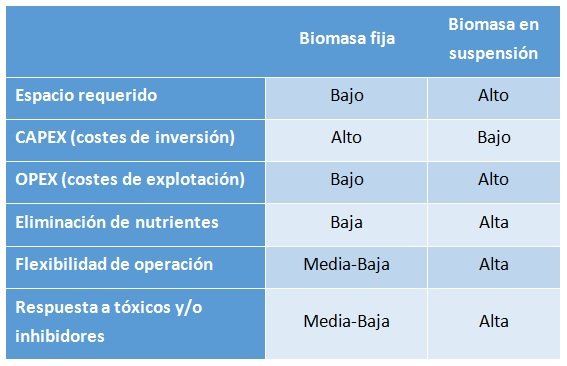

On the other hand, biomass can grow freely, suspended inside the bioreactor, or adhered to a support (fixed biomass). In the conventional process, it grows in suspension, just like in the case of sequential batch reactors (SBR) and in membrane biological reactors (MBR). In disc reactors, biofilters, percolating filters, or moving bed bioreactors (MBBR), biomass grows adhered to the surface of a plastic or sand support. This criterion, whether the biomass grows in suspension or fixed to a support, has a series of practical consequences that should be considered when selecting which technology is the most suitable. The following table summarizes:

Thus, the selection of the most suitable biological process can only be made after analyzing the characteristics of the effluent, the type of industrial process that generates it, the required degree of purification, and the overall needs of the client. Condorchem Envitec has extensive experience in the design, manufacture, installation, commissioning, and operation of biological treatment plants, both aerobic and anaerobic, tailored to the specific needs of its clients.

There are unique configurations that combine the advantages of both systems. This is the case with the BioCarb® reactor, which is an exclusive patented model by Condorchem Envitech and is based on the development of a fixed bed aerobic reactor whose filling material is granulated lignite coal. The coal filters, adsorbs, and serves as a support for the biofilm, in addition to providing microorganisms with minerals and trace elements. On the other hand, the adsorption process makes a dual contribution to the process by smoothing out peaks in contaminant loads and increasing the residence time of contaminants inside the reactor, allowing for the degradation of persistent organic compounds. The BioCarb® reactor has proven to be particularly effective in treating difficult-to-biodegrade contaminants and those with color. Furthermore, the immobilization of biomass on the surface of the lignite coal allows for a combined biological and physicochemical treatment of wastewater in a single stage.

Regarding anaerobic systems, Condorchem Envitech’s extensive experience has led to the use of technologies such as UASB (upflow anaerobic sludge blanket reactor), RAFAC® (upflow anaerobic contact reactor), and RAC® (anaerobic contact reactor), all characterized by their high efficiency, producing clear effluents and transforming organic matter into biogas and stabilized organic fertilizer.