Condorchem Envitech offer

Condorchem Envitech designs and manufactures venturi scrubbers to treat atmospheric emissions, most notably inorganic compounds, dust and particles. The design of each system is tailored to each specific application, with the scrubber being adapted to the customer’s emissions and process flow.

Venturi scrubbers are an efficient solution for eliminating dust and particles, whether they be fine, sticky or hygroscopic particles.

Venturi scrubbers can be used to eliminate small particles (<1 µm) from a gas stream, as well as eliminating larger particles, although energy consumption should be considered in the latter case, as it can be considerably higher than with small particles. In some venturi scrubber models it is possible to vary the width of the throat section, allowing the separator to be adjusted for variable flow rates, thus maintaining high performance.

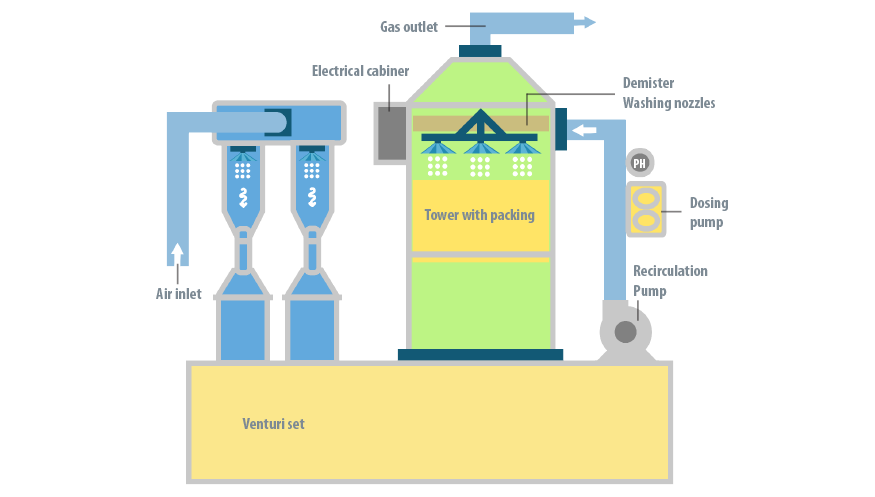

This physical-chemical atmospheric emission treatment system combines an increase in the velocity of the air entering the system with the action of a chemical product.

The main features of our venturi scrubbers are as follows:

- The air being treated flows downstream through a throat, accelerating as it does so.

- It then travels through a packed column, over a large contact surface.

- The scrubbing solution is continuously sprayed through the nozzles by the centrifugal pump and it is automatically replenished as required by the ARRS.

- The automatic water refill system (AWRS) ensures that the working liquid level is maintained.

- There is a scrubbing solution tank at the base of the column.

Our venturi scrubbers

Technical characteristics

- Polypropylene scrubber and venturi structure

- Lower tank for water containment with maintenance accessories

- Lower drain and automatic exhaust valve

- Water and chemical refill systems

- 3-level blow down/refill control

- Manhole for inspections and maintenance

- Scrubbing water ramp

- Centrifugal water circulating pump, vertical or horizontal shaft, stainless steel or polypropylene

- Control panel

| Flow rate (m3/h) | Dimensions (m) | Power (kW) |

| 1.000 | 1,2 x 1,5 x H 3,3 | 2,5 |

| 5.000 | 1,6 x 2,0 x H 3,8 | 10 |

| 10.000 | 1,8 x 2,5 x H 4,1 | 18 |

| 20.000 | 2,0 x 2,5 x H 5,0 | 36 |

| 30.000 | 2,5 x 2,5 x H 5,5 | 45 |

| 40.000 | 3,0 x 3,0 x H 5,8 | 65 |

| 50.000 | 3,0 x 3,5 x H 6,0 | 88 |

| 60.000 | 3,5 x 3,5 x H 6,6 | 95 |

Benefits

- The venturi scrubber allows fine-particle dust to be eliminated from gas streams using wet scrubbing technology.

- Thus, the high air-water contact facilitates the transfer of pollutants from air to water.

- This is highly versatile technology which can eliminate up to 98% of pollutants.

Applications

- Oil industry

- Food industry

- Energy industry

- Wood industry

- Textile industry

- Ceramics industry

- Chemical industry

- Cosmetics industry

- Metallurgical industry

Introduction to the venturi scrubber

Venturi scrubbers are highly efficient air treatment systems that remove particle emissions resulting from the release of exhaust gases generated in different industrial processes.

Venturi scrubbers have several advantages over filters and other dust collecting systems. The main advantages are their compact size and the fact that they are more effective at treating gas streams loaded with particles that contain moisture and/or are at high temperatures. Another benefit is their ease of maintenance and the variety of materials with which they can be made.

In addition to having a system fan and recirculation pump, venturi scrubbers are solid state devices. These particle scrubbers have continuous "blow down" of the scrubbing liquid along with fresh water make-up which decreases the frequency of cleaning. As an additional option, a set of internal nozzles, complete with piping, valves, and chemical injection ports, provide a clean-in-place manifold system which makes these scrubbers relatively easy to maintain.

A standard venturi scrubber features a scrubbing vessel with an area called a throat to facilitate particle collection. Other system components include a system fan, recirculation pump, mist eliminator, and exhaust stack. All venturi scrubbers feature automation controls, ensuring minimal operator interface, greater safety, and easy start-up and operation with the press of a button.

Venturi scrubber operation

When the stream passes through the venturi scrubber, it is scrubbed at high speed in a concurrent stream and subjected to high acceleration and turbulence due to the reduction in diameter, allowing it to trap dust particles and pollutants.

As it passes through the tower scrubber, the air is scrubbed at a low speed across a large contact surface. The most suitable type of packing is used within the scrubbing section to ensure a larger gas-liquid contact surface.

Finally, the stream passes through a demister, which traps all of the droplets, with the stream now purified for the following treatment process or to be released into the atmosphere.