The ENVIDEST DPM series thermal vacuum evaporator is designed to treat aqueous-based streams with a low contaminant load. The equipment can be manufactured to operate using saturated steam or hot water to heat the product to be concentrated. The condensation of the generated vapour is carried out by supplying cooling water.

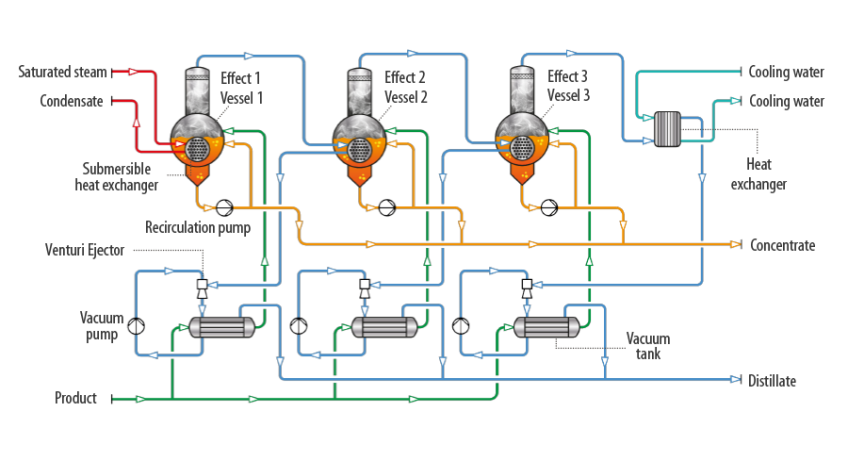

It is available in single-effect or multi-effect (double and triple) versions. The multi-effect versions are notable for their high energy efficiency, as they utilize the latent heat of generated vapour, thereby reducing the energy consumed.

Its modular construction allows for an increase in production capacity without a significant rise in energy consumption, and the configuration of its components (evaporator, heat exchanger, and electrical panel) makes installation easier in different orientations.

The operation of the equipment is fully automatic - 24 hours a day.

Our evaporators ENVIDEST DPM 1

Main features

- Technology: Evaporation with thermal energy

- Single/Multi-Effect: Single-Effect; Multi-Effect

- Thermal Energy for Evaporation: Saturated steam or hot water

- Thermal Energy for Condensation: Cooling water

- Vacuum 1st/2nd/3rd Effect: ≈ 310/200/125 mbar

- Evaporation Temperature 1st/2nd/3rd Effect: ≈ 70/60/50 °C

- Evaporation Vessel: Horizontal

- Droplet Separator: Perforated disk

- Heat Exchanger for Heating: Submersible u-tube

- Vacuum System: Venturi Ejector

- Control Unit*: PLC Siemens with HMI touch screen

- Protection: IP54

- Electricity Supply**: 400 V III + PE 50 Hz

- Standard Manufacturing Material: 1.4401/1.4404 (AISI 316/AISI 316L)

- Special Anti-corrosion Manufacturing Material***: 1.4410 (Superduplex 2507)

* Different PLC manufacturer available on request

** Different voltage supply available on request

*** Consult other available material options

Diagram

Technical specs

| Parameter | Unit | 4000 | 5000 | 8000 | 10000 |

|---|---|---|---|---|---|

| Capacity* | L/day | 4000 | 5000 | 8000 | 10000 |

| Electricity Consumption | kWh | 4 | 4 | 4 | 4 |

| Thermal Energy for Evaporation | kWht | 130 | 160 | 250 | 315 |

| Thermal Energy for Condensation | kWht | 130 | 160 | 250 | 315 |

| Evaporator (L x W x H) | mm | 3400 x 1200 x 3370 | 3400 x 1200 x 3875 | 3400 x 1200 x 3875 | 3400 x 1200 x 3940 |

| Heat Exchanger (L x W x H) | mm | 500 x 450 x 3370 | 900 x 910 x 3875 | 900 x 910 x 3875 | 900 x 910 x 3940 |

| Electrical Panel (L x W x H) | mm | 800 x 500 x 2000 | 800 x 500 x 2000 | 800 x 500 x 2000 | 1000 x 500 x 2000 |