Sections

- The Olive Industry and the Environment

- Effluents Produced by the Olive Industries

- Treatment of Effluents from the Olive Industries

- Conclusions

The Olive Industry and the Environment

The olive industry has a significant presence in various regions of the world. Although olives are partly destined for direct consumption, their main use is the production of olive oil, a product highly valued for its well-known nutritional properties and health benefits.

However, the oil production process generates large volumes of liquid and solid waste with a high pollution potential. The improper disposal of these by-products, especially olive mill wastewater (alpechines), can have a considerable environmental impact. Therefore, environmental regulations establish strict restrictions on their management, promoting practices of reuse, valorization, and recycling aimed at minimizing their effect on ecosystems.

Effluents Produced by the Olive Industries

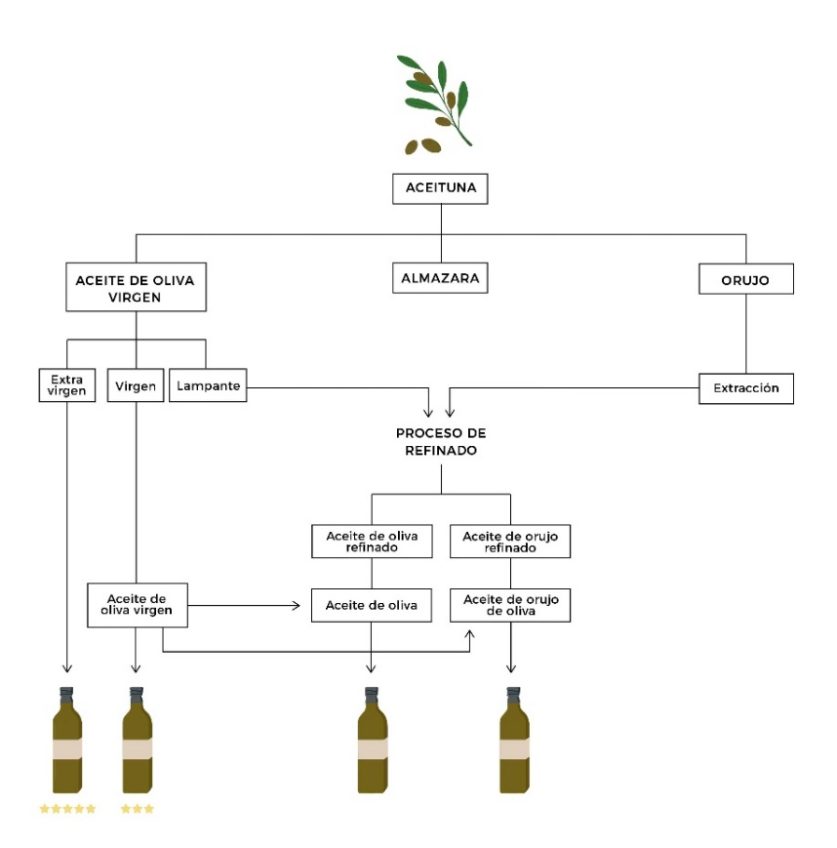

Olive oil is obtained through two methods:

- The traditional batch pressing method, consisting of crushing and pressing the olives.

- Continuous centrifugation method, in which the oil is extracted by centrifuging a mixture of crushed olives and hot water.

In both systems, three phases are produced: a) the oil, b) the solid phase, and c) the aqueous phase.

The oil and the solid phase, called pomace, represent approximately 20% and 30% respectively of the weight of crushed olives. The rest of the weight is the water contained in the fruit itself, which forms part of the liquid effluent called alpechín (olive mill wastewater).

The disposal or treatment of by-products from the olive oil industry, especially alpechín, constitutes a serious problem for this industrial sector.

The pomace consists of the pulp and pits of the olive and also contains moisture and oil in proportions that vary depending on the production system from which it comes:

- Pressing system: 25-30% moisture and 5-6% oil

- Centrifugation system: 45-50% moisture and 4-7% oil.

The pomace itself does not represent an environmental problem, as it has traditionally been used as raw material in the pomace oil industry. In this sector, after a drying process, pomace oil is extracted, generating as a solid by-product the extracted pomace, also known as orujillo. This residue has significant energy value and is commonly used as fuel in the pomace oil mills, olive mills, or other industrial facilities, thus contributing to a more sustainable and circular model.

Fat-free pit fragments are used as fuel and also in the manufacture of activated carbons. On the other hand, the high content of organic and mineral matter in orujillo makes its use possible as organic fertilizer or as an ingredient in compost production, mixed with other agricultural by-products.

Production and Risks of Alpechín

The remaining aqueous liquor is alpechín. It is composed of vegetation water, the soft tissues of the olives, and the water used in the different stages of oil production. The volume of alpechín produced is 0.5-1.5 liters per kilogram of crushed olives.

Alpechín is a dark liquid composed of:

- 83-94% water.

- 4-16% organic matter (polysaccharides, proteins, organic acids, polyphenols).

- 0.4-2.5% salts (carbonates, phosphates, K, Na), which have a high pollution potential.

The following table is indicative of the compounds contained in alpechín, depending on the olive oil extraction process used:

| Unit | Pressing Method | Centrifugation | |

|---|---|---|---|

| Organic Substances | |||

| Total sugars | g/l | 20-80 | 5-26 |

| Nitrogenous substances | g/l | 5-20 | 1.7-4 |

| Organic acids | g/l | 5-10 | 2-4 |

| Polyols | g/l | 10-15 | 2-5 |

| Pectins, mucilages, tannins | g/l | 10-15 | 2-5 |

| Polyphenols | g/l | 10-24 | 3-8 |

| Fats | g/l | 0.3-10 | 5-23 |

| Unit | Pressing Method | Centrifugation | |

|---|---|---|---|

| Inorganic Substances | |||

| Total P | g/l | 1.1 | 0.3 |

| K⁺ | g/l | 7.2 | 2.7 |

| Ca⁺² | g/l | 0.7 | 0.2 |

| Mg⁺² | g/l | 0.4 | 0.1 |

| Na⁺ | g/l | 0.9 | 0.3 |

| Fe⁺³ | g/l | 0.07 | 0.02 |

| CO₃⁻² | g/l | 3.7 | 1 |

| SO4⁻² | g/l | 0.4 | 0.15 |

| Cl⁻ | g/l | 0.3 | 0.1 |

Discharging alpechín affects the quality of surface waters, increasing concentrations of organic and inorganic solids, potassium, phosphorus, and heavy metals. Likewise, such discharges cause a decrease in dissolved oxygen, sometimes to anoxic levels, leading to bad odors, development of harmful microorganisms, suffocation, and death of aquatic fauna.

Production and Risks of Alperujo

Alperujo is a concentrate obtained in the olive oil production process and is composed of the various residues left from the olive after the oil has been extracted, that is:

- The solid parts.

- The alpechín.

- The oil residues that could not be extracted after the centrifugation process.

Alperujo was considered waste until relatively recently, but now it is considered a by-product, as it can be valorized and reused for the following purposes:

- Pomace oil. It is made from the fat that remains adhered to the residues from the extraction of extra virgin and refined olive oil. It is a lower quality oil and has presented toxicity problems on several occasions.

- Fuel for generating electrical and thermal energy. The only drawback is the large amount of ash produced when burning alperujo.

- Thanks to its high content of organic matter and micronutrients, it can also be used as a biological fertilizer. The application of alperujo compost in olive groves allows nutrients extracted with the harvest to be returned to the soil. Nowadays, there are various companies dedicated to collecting alperujo from olive mills to obtain the organic matter concentrate and resell it to the same mills as fertilizer.

- Additionally, alperujo also contains antioxidant components of interest to the pharmaceutical industry and can be used for the production of pectins, a compound used in the food industry.

- In recent years, numerous studies have been carried out aimed at valorizing the by-products generated in the olive oil industry. In the case of pomace, separating the pulp and pits not only facilitates a more efficient extraction of residual oil but also allows better use of the pomace pulp and orujillo. These materials contain compounds of interest such as cellulose, hemicellulose, sugars, pectins, and proteins, making them suitable for use in animal feed and other industrial applications.

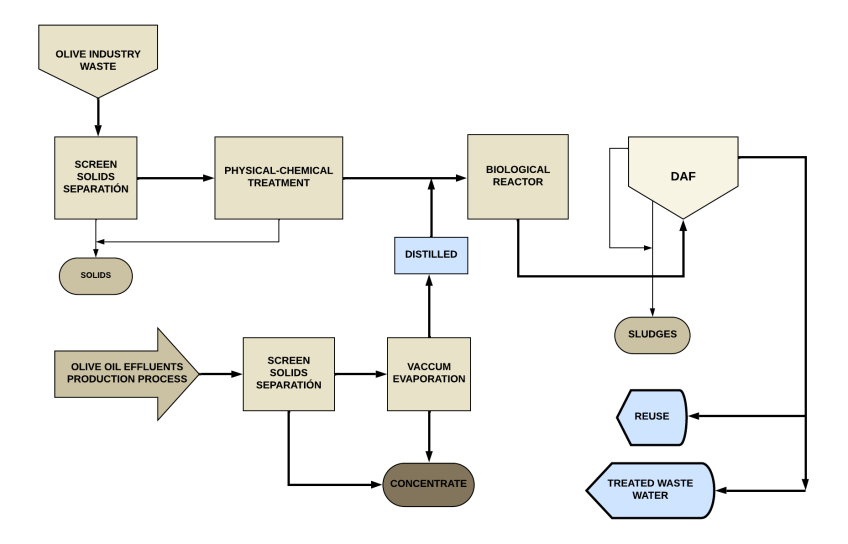

To obtain these by-products from alperujo, it must be treated to separate the concentrated matter from the purified waters. There are different alternatives for treating alperujo as waste, but the technology that allows obtaining a higher quality concentrate for its subsequent reuse as a by-product is vacuum evaporation.

Treatment of Effluents from the Olive Industries

Evaporation ponds are the most widespread solution to avoid discharging effluents produced in the olive industry. It is the only method that does not consume large amounts of energy, as it works through the evaporation of water, which depends on the climate and ranges between 5 and 10 mm per day.

However, the construction of evaporation ponds does not meet the sector’s needs, as production growth far outpaces the capacity to build these ponds, so they end up not satisfying either the companies’ needs or the environmental requirements of the authorities.

Moreover, since they depend on climatic conditions, disastrous situations can occur, such as in the case of heavy rains.

Technologies and Treatment Methods

There are different processes and technologies for treating effluents produced by the olive industry, among which stand out:

Physicochemical Processes

These methods aim to reduce the pollutant load of alpechines through processes such as:

- Coagulation-flocculation: Chemical agents are used to agglomerate suspended particles, facilitating their separation.

- Filtration and sedimentation: Allow removal of suspended solids.

- Advanced oxidation: Application of ozone, hydrogen peroxide, or ultraviolet radiation to degrade toxic organic compounds.

Biological Systems

These are sustainable processes that use microorganisms to break down organic matter:

- Anaerobic digesters: Convert alpechines into biogas, which can be used as a renewable energy source.

- Composting: Mixing alpechines and other organic wastes to obtain a nutrient-rich fertilizer.

- Stabilization ponds: Natural systems where microorganisms degrade contaminants.

Vacuum Evaporation

A vacuum evaporator concentrates the organic matter, separating it from the water contained in alperujo. This concentrate can then be applied to the various uses mentioned above.

For olive mills with medium and high production levels, which generate a large amount of alperujo, vacuum evaporation is a very interesting solution, as it can be profitable within a reasonable time frame and offers excellent results from the perspective of waste management.

Economically, the results obtained with this technology allow generating certain savings in variable costs, as the sludge that must periodically be sent to waste managers is eliminated, and at the same time, fertilizer is obtained for planting new olive trees without needing to purchase it from suppliers.

Waste Utilization

The wastes obtained in the olive oil production process have various profitable applications:

- Energy production: Pomace can be used as biomass to generate electricity and heat.

- Extraction of valuable compounds: Phenols present in alpechines have antioxidant properties and can be used in the pharmaceutical and cosmetic industries.

- Biofertilizers: From the controlled transformation of organic waste.

The sludge obtained after biological and physicochemical processes is not rich in organic matter, as these methods aim precisely to remove that matter and obtain sludge that must be sent to a waste manager. Thus, we find sludge containing a very low-quality concentrate and that will also contain residues of the products and bacteria used to eliminate alperujo, which further discourages its use if the goal is to obtain a by-product that can be reused as fertilizer.

Vacuum evaporation allows obtaining concentrates rich in organic matter, which can be reused for different purposes.

Conclusions

The olive industry generates effluents with high pollutant loads, which cannot be discharged into the environment due to their toxicity and environmental impact.

There are various ways to treat these wastewaters, such as physicochemical processes, biological processes, chemical oxidation, and evaporation ponds, but these are costly and complex and only partially solve the problem.

Management of olive waste using traditional technologies still faces challenges such as:

- High installation and operation costs of treatment plants.

- The need to raise awareness among producers about sustainable practices.

- The integration of technological solutions in small and medium-sized olive mills.

Treatment of waste obtained after olive oil production and its valorization is crucial to improve the sector’s competitiveness and profitability.

Vacuum evaporation is an efficient solution, as it can be profitable within a reasonable time frame and offers excellent results from the perspective of waste management and the quality of treated wastewater.

Sustainable management of discharges and waste from the olive industry not only mitigates its environmental impact but also represents an opportunity to generate value from by-products.

The future lies in the implementation of more efficient technologies, such as vacuum evaporators, as well as promoting a circular economy model that maximizes the use of generated waste.

Bibliography and References

- www.mapa.gob.es/es/agricultura/temas/producciones-agricolas

- THE ALPECHIN: A MEDITERRANEAN PROBLEM

(www.juntadeandalucía.es/medioambiente) - Systems for the Treatment of Alperujo and Alpechín

- Obtaining By-products from Alperujo Using Vacuum Evaporators | Condorchem Enviro Solutions

- Pollution in the Olive Sector, Solutions Under Development | Condorchem Enviro Solutions