Condorchem Envitech Offer

Condorchem Envitech designs, manufactures, and installs activated carbon filters for the control and reduction of the following types of atmospheric emissions:

- Volatile Organic Compounds (VOCs) such as hydrocarbons, organic solvents, aromatic compounds, and other volatile organic pollutants.

- Treatment of unpleasant odor emissions generated in industrial processes, wastewater treatment plants, landfills, and waste treatment facilities.

- Toxic gases such as sulfur dioxide (SO2), nitrogen dioxide (NO2), chlorine (Cl2), and other hazardous gaseous pollutants present in industrial emissions.

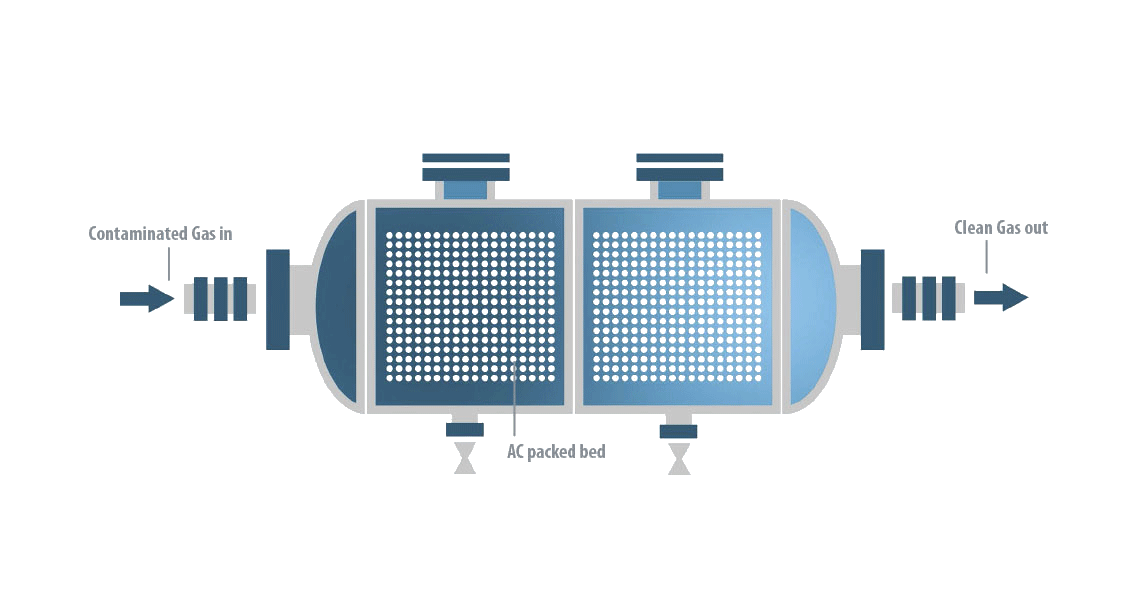

Our activated carbon filters enable different construction options depending on the flows to be treated. For small and moderate flows, the treatment systems are of the longitudinal flow type, while for high flows the manufactured systems are of cross flow.

The knowledge and experience of Condorchem Envitech has made it possible to adapt the design of each individual case. We make adaptations of both the specific working conditions, pressure and temperature, and specific building conditions such as areas of significant seismic activity and regulations and adaptations to local and international building regulations.

Our filters have detected systems that continuously measure the degree of saturation of the active coal. This system based on the continuous measurement of the increase in the mass of active coal depending on the degree of saturation of the active coal, allows for the maximal harnessing of the coal and a significant saving on the operating and management costs of active coal.

Using software developed by Condorchem Envitech the different inlet flows are simulated on the filters, obtaining the main values of the process to determine both the building characteristics and the treatment guarantees of the process.

Our AC filters

Advantages

- Relatively low investment cost in comparison with other technologies.

- A totally automated system without the need for labor costs in the operating process.

- Maximal harnessing of the active coal using an automatic and continuous control system of the percentage saturation of the active coal using load cells.

- Specific design for particular projects using software developed by Condorchem Envitech that makes it possible to adapt to conditions requested by the client.

- Structural adaptation to seismic zones and to local climate conditions

- Low exposure to external loads (wind and seismic)

- Our design achieves a very low load loss, such that there is no need for an additional fan, and it is possible to harness the pressure of the gas flow itself.

- Easy loading and unloading of the filter bed

- Overpressure and vacuum protection system, using a safety valve and / or bursting disc

- Optimization of the life of the active coal bed

Construction materials

- Equipment built in stainless steel.

- Manufacturing in another type of material according to the needs of the client.

- Maximum resistance to internal and external corrosion.

- 30 years of useful life guaranteed.

Applications

The technique is applicable to a wide variety of industrial emissions, of which the following are the most common:

- Venting from the ullage system of a thermosolar plant

- Wastewater treatment plants: Pumping wells, drainage wells, thickeners, pre-treatment and sludge dehydration.

- Food industry: smells from slaughterhouses, animal fat treatment, fish processing plants

- The chemical and pharmaceutical industry: gases from reactor vents

- Treatment of biogas prior to energy recovery

Special design for solar thermal power plants

Venting from the ullage system of a CSP plant contain benzene, phenol, toluene and xylene. These pollutants are toxic, especially benzene, and there are therefore strict legal limits on their emissions. These flows need to be treated before being released into the atmosphere.

The most appropriate treatment technology for these emissions are active coal filters.

The process is very simple and consists of passing the air to be treated through a coal bed which retains the pollutants. This bed is loaded until it is saturated and loses its absorbent capacity. On reaching this point, one may opt to discard the coal and replace it, or regenerate the coal with steam or an inert gas. This last option, moreover, allows us to recover the solvents and reused them in the production process.

Condorchem Envitech has extensive experience in the design of coal filters for treating VOCs in general and most especially in the treatment of the venting of the ullage system of solar thermal plants.

As mentioned above, a software developed by Condorchem Envitech let simulate the different inlet flows on the filters, obtaining the main values of the process to determine both the building characteristics and the treatment guarantees of the process.

The active coal filter process is produced by the phenomenon of adsorption of a molecule in a porous area. For this effect to be possible, it is necessary to obtain, through the plant design, basic parameters such as the flow speed, residence time, etc.

Introduction to activated carbon filters

Activated carbon filters can be used to adsorb certain contaminants present in industrial gases on solid media, leaving them free of harmful compounds. This is a non-destructive technology for treating the VOCs and odors present in industrial gases.

The contaminants present in the gases adhere to the surface of the activated carbon particles according to an equilibrium operation. Once it is exhausted and no more contaminant molecules can be adsorbed, changing the environmental conditions can produce the desorption of the contaminant and thus regenerate the activated carbon for reuse.

Functioning/operation of the activated carbon filtration

Activated carbon filtration treatment is based on the adsorption capacity of activated carbon for removing low concentrations of a wide variety of pollutants (e.g. VOCs, hydrogen sulphide, siloxanes, chlorinated and aromatic hydrocarbons and dioxins).

In classical activated carbon filtration, the adsorption occurs in a direction in which the contaminant molecules adhere to the carbon granules. When the filter is saturated, it must be replaced and regenerated (by incineration or thermal reactivation).

Activated carbon filtration equipment consists of:

- A column of activated carbon: a tank made of stainless steel whose capacity varies depending on the flow to be treated

- Selector valve: 5-way valve (manual or automatic) with filtering and washing positions

- Activated carbon: made from non-granite carbonaceous materials. The raw material is chosen according to the liquid to be treated. One of the properties of activated carbon is the adsorption capacity of a wide variety of different molecules.