Thermal Vacuum Evaporator-Crystallizer

The DESALT DRY series vacuum evaporator-crystallizer is designed to obtain solid or semi-solid concentrates, as well as to recover valuable raw materials, such as metals and salts. The equipment can be manufactured to operate using saturated steam or hot water to heat the product to be concentrated. The condensation of the generated vapour is carried out by supplying cooling water.

This evaporator can be manufactured with a screw conveyor inside the evaporation vessel to homogenize the product during the concentration phase, which facilitates the automatic discharge of the final product.

The operation of the equipment is semi-automatic or automatic (depending on the model) - 24 hours a day.

Our evaporators DESALT DRY

Main features

- Technology: Evaporation with thermal energy

- Single/Multi-Effect: Single-Effect

- Thermal Energy for Evaporation: Saturated steam or hot water

- Thermal Energy for Condensation: Cooling water

- Vacuum: ≈ 200 mbar

- Evaporation Temperature: ≈ 60 °C

- Evaporation Vessel: Horizontal

- Droplet Separator: Raschig rings

- Heat Exchanger for Heating: Shell and tube

- Vacuum System: Venturi Ejector

- Control Unit*: PLC Siemens with HMI touch screen

- Protection: IP54

- Electricity Supply**: 400 V III + PE 50 Hz

- Standard Manufacturing Material: 1.4401/1.4404 (AISI 316/AISI 316L)

- Special Anti-corrosion Manufacturing Material***: 1.4410 (Superduplex 2507)

* Different PLC manufacturer available on request

** Different voltage supply available on request

*** Consult other available material options

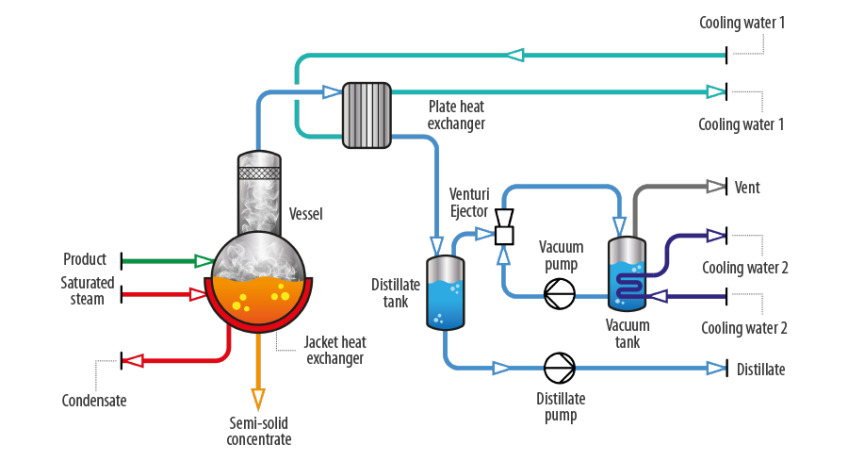

Diagram

Technical specs

| Parameter | Unit | 500 | 750 | 1000 | 1500 | 3000 |

|---|---|---|---|---|---|---|

| Capacity* | L/day | 500 | 750 | 1000 | 1500 | 3000 |

| Electricity Consumption | kWh | 2,7 | 2,7 | 2,7 | 4,1 | 7,4 |

| Thermal Energy for Evaporation | kWht | 16 | 24 | 31 | 47 | 94 |

| Thermal Energy for Condensation | kWht | 16 | 24 | 31 | 47 | 94 |

| Length | mm | 2400 | 2810 | 3070 | 4230 | 4880 |

| Width | mm | 1670 | 1760 | 1970 | 1990 | 2450 |

| Height | mm | 2600 | 2680 | 2715 | 2965 | 3546 |

* Data refer to clean water when working continuously in standard conditions (T = 20 °C, P = 1013 mbar).