Project details

- Client: Cemex factory, Broceni

- Year: 2014

- Location: Broceni, Latvia

- Sector: Glass, ceramics, cement and other materials

- Division: Industrial wastewater / Waste recovery

Project description

CEMEX is a world leader in the production and commercialization of cement, concrete, aggregates and mortar, and one of the largest producers of white cement in the world. It has more than 43,000 employees and recorded global sales of $14.127 billion in 2015.

Request: To change an external gas bypass dust management system within the cement manufacturing process for a system that can reuse it in the clinker, after washing and filtering to remove any salts it may contain. The salt water generated in this washing process should be treated properly. 10,500 tons/year of bypass powder needs to be treated, which will involve a washing and filtration plant and a crystallizer for 300 L/h of salt water.

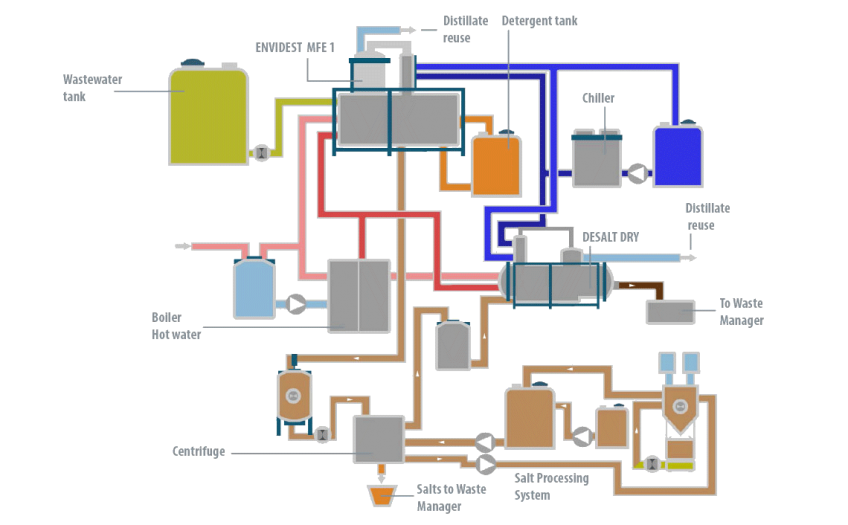

Solution: 1 ENVIDEST MFE-1 3600 SW vacuum evaporator (with steam) + 1 DESALT DRY 3000 SW vacuum crystallizer (with steam) + peripherals.

Results

TRUE ZLD Recovery of potassium salts to sell as a by-product and reuse of distilled water in the production process.