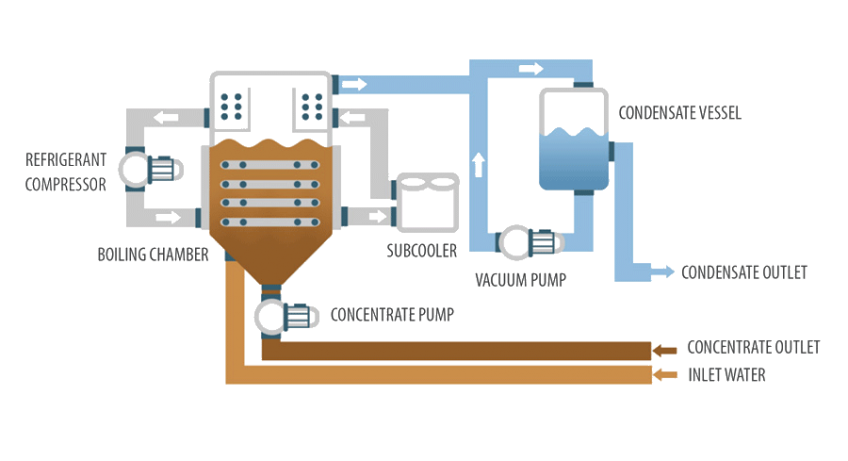

The vacuum evaporator ENVIDEST LT VS series is designed to treat industrial liquid effluents. The equipment operates with electrical energy. Its heating and condensation system is based on a heat pump unit.

Standard manufacturing in 1.4401/1.4404 (AISI 316/AISI 316L) stainless steel. According to the wastewater to be treated, the parts of the equipment in contact with the fluid can be made of special corrosion-resistant alloys.

Fully automatic operation of the equipment 24 hours a day.

Our evaporators ENVIDEST LT VS

Main features

- Vessel:A detachable vertical evaporation vessel, manufactured in stainless steel. Equipped with a manhole and an inspection glass.

- Submersible heat exchanger: The evaporation vessel houses in its flanged lower section a coil-type stainless-steel heat exchanger to heat the product to be concentrated.

- Condensation section: A coil-type stainless-steel heat exchanger is positioned in the flanged upper section of the vessel and is intended for the condensation of the vapour produced.

- Demister, located between the evaporation and condensation zones, to capture droplets of the wastewater within the vapour produced.

- Distillate tank: The distillate is stored in a stainless-steel tank and is discharged by a centrifugal pump controlled by level switches. Depending on the model, it is either an option or already included in the standard configuration.

- Heat pump unit uses the refrigeration cycle to heat the wastewater and condense the vapour produced, as well as to cool the vacuum circuit. It consists of a compressor using an environmentally friendly refrigerant, R-407C freon gas, a thermostatic expansion valve to regulate the refrigerant pressure, and fans for reducing the refrigerant temperature.

- Vacuum generation system consists of a Venturi ejector and a centrifugal pump or a liquid ring vacuum pump (depending on the model) and a stainless-steel vacuum tank containing chilled water to cool the vacuum circuit. The vacuum tank is equipped with a coil-type heat exchanger through which the refrigerant circulates.

- Concentrate discharge: Recirculation and automatic discharge of concentrate through the recirculation pump. The duration of the concentration cycle is programmed with a timer.

- Instrumentation: Digital and analogue control instruments for the automatic monitoring of the system.

- Electrical command and control panel with emergency stop. IP54/IP55 protection (depending on the model). The power supply of the panel is 400 V, 50 Hz. Siemens PLC with touch screen for visualization and control of operating data.

- Supporting structure: Unit mounted on a stainless-steel skid.

Optional features

- Teleservice Control System for remote assistance.

- Manufacturing with special material on request.

- Other voltage supply on request.

- Other PLC manufacturer on request.

Diagram

Technical specs

| Parameter | Units | 250 | 500 | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5500 | 7000 | 9000 | 10000 | 12000 | 15000 | 18000 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | L/day | 250 | 500 | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5500 | 7000 | 9000 | 10000 | 12000 | 15000 | 18000 |

| Electrical consumption | kWh | 4,7 | 5,9 | 5,3 | 8,0 | 13,0 | 16,9 | 22,2 | 24 | 29,7 | 40,9 | 64,4 | 64,8 | 89 | 110 | 120 | 160 |

| Dimensions (L x W x H) | mm | 2050 x 830 x 1900 | 2100 x 870 x 2250 | 2200 x 1000 x 2200 | 2200 x 1000 x 2400 | 2800 x 1300 x 2400 | 2900 x 1250 x 2420 | 3000 x 1350 x 2700 | 3300 x 1350 x 2750 | 3500 x 1350 x 2840 | 3600 x 1500 x 3020 | 4000 x 1500 x 3250 | 4000 x 1500 x 3250 | 4500 x 2000 x 3310 | 4500 x 2000 x 3300 | 5600 x 2250 x 3900 | 5600 x 2400 x 4155 |